Extreme Pressure (EP) Grease

As the name suggests, extreme pressure (EP) grease is specially formulated to withstand high-pressure conditions. It is particularly suitable for heavy-load, high-impact, or high-vibration working environments, such as heavy machinery, mining equipment, or high-speed industrial machinery. In such harsh conditions, ordinary greases often struggle to maintain effective lubrication, leading to mechanical failures. EP greases, enhanced with special additives, can provide long-lasting lubrication even under extreme conditions.

Key Features of EP Grease

The excellent durability of EP grease is mainly due to its composition. It typically contains special extreme pressure additives, which form a protective film under high pressure to prevent direct metal-to-metal contact, significantly reducing wear and damage. Additionally, the base oils and thickeners in the grease also contribute to its extreme pressure performance.

However, not every lubrication scenario requires EP grease. The choice should be based on the actual working conditions of the equipment and the manufacturer’s recommendations. Overuse or improper use of EP grease may be counterproductive and negatively affect equipment performance.

Specialized Industrial Grease

In summary, industrial greases marked as EP represent high-performance, extreme-pressure-resistant lubricants. They ensure efficient lubrication in heavy-load and harsh environments, extend equipment service life, and help maintain reliable production operations.

A planetary gearbox is a mechanism designed to reduce motor speed while increasing torque. Its internal planetary gears are the core components of the gearbox, and special attention must be paid to lubrication when operating under extreme high or low temperatures. A high-quality, fully synthetic grease should possess the following four key functions to meet the lubrication requirements of planetary gears.

1. Lubrication and Wear Protection

During high-speed operation, the teeth of planetary gears engage and rub against each other rapidly, which can accelerate gear wear. Using grease forms a lubricating elastic film on the gear surfaces, reducing direct metal-to-metal contact and friction, thereby minimizing gear tooth wear.

2. Enhance the Durability of Planetary Gear Contact Surfaces

The contact stress on gear teeth is a primary factor leading to reduced gear strength. The lubricating film formed by grease helps distribute the stress across the gear surface, thereby improving the durability of the gears.

3. Prevent Adhesive Gear Surface Damage

Adhesion is a common failure mode in gear transmissions. Specifically, when the load and speed on the gear mesh exceed the limit that the lubricating film can withstand, the film may rupture, causing direct friction between the contacting gear surfaces and resulting in wear. As friction intensifies, the temperature of the gear surfaces rises rapidly, which may lead to adhesion and gear surface damage. Grease, with its anti-adhesion properties, load-bearing capacity, and extreme pressure (EP) characteristics, ensures effective separation between gear teeth, effectively preventing adhesive damage.

4. Reduce Transmission Noise and Vibration

Gear vibration and noise can arise from multiple factors, making the choice of grease particularly important. A suitable gear grease, due to its viscosity, can significantly reduce gear vibration, impact, and noise. However, the effect on vibration and noise may vary depending on the lubrication method and the specific type of grease used.

Qin Jingteng, Member of the Standing Committee of Guangming District, Visits EUBO for Inspection and Research

Recently, Qin Jingteng, Member of the Standing Committee of Guangming District, along with personnel from the District Committee’s United Front Work Department, the Federation of Industry and Commerce, Matian Subdistrict Office, and the Matian Community Enterprise Service Center, visited EUBO New Material to conduct an inspection and understand the company’s development, while listening to enterprise needs. Chairman Yue Fengshu provided Qin and his delegation with a report on EUBO’s development.

Qin and his team held a meeting with the company’s senior management. At the meeting, R&D Director Li Shicheng introduced the company’s product development efforts, and Dr. Yang Bin, Assistant to the General Manager, reported on recent industry-university-research cooperation projects with the Institute of Chemistry, Chinese Academy of Sciences, and Southern University of Science and Technology, as well as the progress of scientific research projects. Qin expressed strong approval and support for these initiatives.

Qin also inquired about any challenges the company faces in production and operations that may require government support, and sought opinions on the enterprise services provided by the Matian Subdistrict Office. He emphasized that, as a key enterprise in Guangming District, EUBO will receive strong support from local party committees, government departments, and relevant authorities. Any difficulties encountered during development will be actively coordinated and resolved. Finally, Qin encouraged EUBO to continue innovating boldly under new business models and formats, strengthen product R&D, and further expand and enhance the company’s capabilities.

Qin highly recognized EUBO’s pragmatic and earnest approach, noting that the company’s products not only yield significant economic benefits but also deliver substantial social value. He expressed hope that EUBO will continue to grow and thrive, rooted in Guangming.

EUBO PUR Hot Melt Adhesive is a versatile, single-component reactive hot melt adhesive. It exhibits excellent initial tack at room temperature and shows outstanding compatibility with a wide range of substrates, including plastics, metals, ceramics, and inorganic glass, quickly achieving positioning strength in a short time.

This product is especially suitable for bonding frames and display screen bezels in various consumer electronics, particularly for adhesion between metal frames and plastic parts. Its fast curing and high initial tack provide significant pressure-free bonding benefits (eliminating the need for traditional pressing steps), while maintaining pressure-sensitive characteristics for approximately 10 minutes after dispensing, facilitating easy positioning and handling.

Single-component, Solvent-free: Convenient to use, environmentally friendly, and safe.

Enhanced Production Efficiency: Shortens assembly time, improving efficiency, throughput, and product yield.

Excellent Mechanical Performance: After curing, the adhesive forms a tough matrix, providing outstanding drop-resistance for the final product.

High Bonding Efficiency: Strong initial tack and high final bonding strength, reducing adhesive consumption.

EUBO PUR Hot Melt Adhesive is widely used in the electronics industry, including but not limited to:

Smartphones and tablet screen assembly

Educational devices (learning machines)

GPS navigation devices

Wearable electronics (window bonding, casing structural bonding)

Battery bonding and fixation

Planar sealing

PCB assembly and protection

Post-dispensing Cleanup: Wait until the adhesive cools to room temperature, then remove any excess adhesive that has overflowed at the edges.

Uncured Adhesive Removal: Any remaining uncured adhesive can be scraped off using a blade.

Solvent Wiping: If wiping is necessary at the dispensing site, common cleaning solvents such as toluene or acetone can be used.

Timely Cleaning: Ensure adhesive residues are removed before the adhesive is fully cured.

Heating and Usage Duration: Do not repeatedly heat the adhesive. Once opened, it must be used within 8 hours. Continuous single-time heating should not exceed 8 hours.

Temperature Control: The operating temperature should not be set too high and must be ≤ 130°C to prevent the risk of tube rupture under high temperature and pressure.

Safety Protection: Take care to avoid burns during operation.

Storage Conditions: Store the product in a dry environment with a temperature between 15–25°C.

Packaging Requirements: The product should be kept in vacuum-sealed aluminum foil bags.

Shelf Life: Under the above storage conditions and unopened, the product has a shelf life of 6 months.

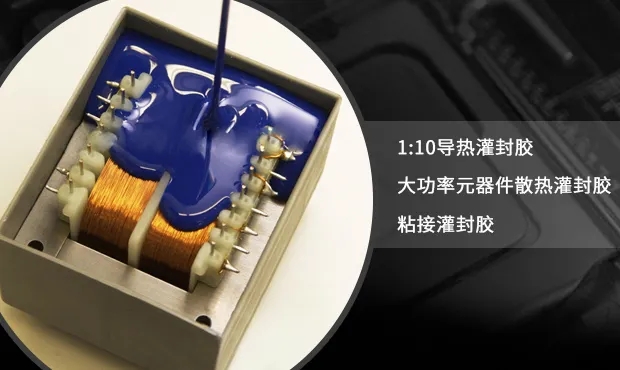

Potting adhesives are indispensable materials in the electronics industry, playing a key role in ensuring the safety, reliability, and longevity of electronic products. Their necessity can be highlighted in the following aspects:

Enhanced Protection and Structural Strength:

Physical Protection: After curing, potting adhesives form a protective layer that significantly enhances the overall structural strength of electronic components, improving resistance to external impacts, vibrations, and mechanical stresses.

Environmental Sealing: They effectively prevent direct exposure of internal components and circuits, providing excellent barriers against water, moisture, dust, and corrosion, thus protecting delicate circuitry from harsh environments.

Improved Electrical Performance and Miniaturization:

Reliable Insulation: Potting adhesives greatly enhance insulation between specialized internal components and complex circuits, preventing short circuits and leakage, ensuring safe operation of the device.

Facilitates Miniaturization: The filling and protection provided by potting adhesives help secure micro-components, supporting lightweight and compact design in electronic products.

Addressing Thermal Challenges:

Modern electronic products feature high precision and high power density, which can easily lead to excessive component temperatures, causing failures and shortening product lifespan.

Potting adhesives—especially thermally conductive types—act as a critical thermal management medium. When applied inside electronic products, they efficiently transfer heat generated by internal components to the casing, significantly improving overall heat dissipation performance.

Ensuring Comprehensive Performance:

High-quality potting adhesives not only provide excellent shock resistance, sealing, and thermal conductivity after curing, but also offer good heat resistance, flame retardancy, weatherability (resistance to thermal cycling, UV, etc.), and long-term stability.

EUBO potting adhesives are designed to meet the needs of electronic products, providing the following key functions:

Structural Reinforcement & Impact Resistance:

Forms a tough protective layer after curing, enhancing the overall structural strength of electronic devices and effectively resisting external impacts and vibrations.

Electrical Insulation & Miniaturization Support:

Significantly improves insulation between internal components and circuits, ensuring electrical safety. Its filling properties also support miniaturization and lightweight design of devices.

Comprehensive Environmental Protection:

Prevents sensitive components and circuits from direct exposure, providing excellent protection against water, moisture, dust, and corrosion.

Multifunctional Performance Assurance:

Once fully cured, the adhesive offers thermal conductivity, flame retardancy, high/low temperature resistance, dust protection, and circuit shielding, ensuring the safe and stable operation of electronic components.

In addition to the core functions, EUBO potting adhesives feature excellent processing and usage characteristics:

Excellent Processability: Low viscosity and strong penetration during potting, fully filling fine gaps and encapsulating components.

High Stability: Components are stable, easy to store, and have a long shelf life, suitable for large-scale automated production lines.

Superior Curing Performance: Minimal filler sedimentation during curing, low risk of phase separation, ensuring uniform and consistent performance.

Outstanding Comprehensive Properties: After curing, exhibits excellent flame retardancy, weatherability, thermal conductivity, resistance to high/low temperature cycles, and water resistance.

EUBO potting adhesives are widely used in electronic components requiring protection, insulation, and thermal management, including but not limited to:

Power & Drive: Transformers, high-voltage packs, rectifiers, filters, drivers, igniters, ignition coils, power controllers, aquarium pumps, energy-saving modules.

Lighting: LED lighting, LED barrier lights, LED modules.

Security & Sensing: Electronic locks, magnetic locks, electronic sensing modules.

Automotive Electronics: Xenon lamps, light boosters.

Others: Capacitors, negative ion generators, etc.

Application Benefits: Provides reliable potting and filling, circuit shielding, electrical insulation, and moisture/water protection for the above components.

EUBO offers a comprehensive range of electronic adhesive products to meet diverse needs, including:

Potting adhesives

PUR hot melt adhesives

Module frame adhesives

Underfill adhesives

Two-component structural adhesives

Coating adhesives

Thermally conductive adhesives

Sealing adhesives

These products are widely applied to various electronic components, ensuring product safety, long-term reliability, and environmental compliance.

Contact EUBO today to obtain professional and reliable electronic adhesive solutions!

From August 8 to 10, 2025, the World Battery & Energy Storage Industry Expo will be grandly held at Area A of the Guangzhou Canton Fair Complex. As a major event for the Asia-Pacific new energy industry, the exhibition will bring together over 2,000 renowned domestic and international companies, showcasing cutting-edge technologies such as lithium batteries, sodium-ion batteries, solid-state batteries, and hydrogen fuel cells, as well as application scenarios in energy storage, electric vehicles, and 3C consumer electronics, driving high-quality development in the new energy sector.

Exhibition Date: August 8–10, 2025

Exhibition Venue: Area A, Guangzhou Canton Fair Complex

EUBO Booth: Hall 4.1, C308

EUBO Focuses on Battery Adhesive & Encapsulation Solutions

In response to the growing demand for encapsulation and bonding in segments such as power batteries, energy storage batteries, and 3C digital batteries, EUBO New Material will showcase a range of electronic encapsulation adhesives at this exhibition, providing reliable bonding and sealing solutions for the battery industry.

Featured Products:

▶ Structural & Adhesive Solutions:

Including PUR hot melt adhesives, epoxy adhesives, acrylic adhesives, and silicone adhesives. Some products employ UV curing technology to achieve fast and precise positioning and efficient assembly, widely used in various structural fixation and module bonding scenarios.

▶ Encapsulation & Protective Materials:

Including conformal coating adhesives, potting adhesives, sealing adhesives, and nano water-repellent agents, providing moisture, dust, corrosion, and mechanical protection for electronic components.

▶ Functional Adhesives:

Including thermal conductive adhesives and electrically conductive adhesives, enhancing heat dissipation, electrical performance, and overall reliability.

These products are widely used in cell encapsulation, battery module assembly, and terminal sealing, compatible with lithium-ion, sodium-ion, and solid-state battery systems. They offer high bonding strength and excellent weather resistance, helping companies build high-performance, safe, and reliable energy storage systems and end products.

On-site Interaction & Engagement

Technical Sharing: Insights into trends in power battery and energy storage encapsulation applications.

Face-to-Face with Experts: Personalized product selection and application consultation.

Case Demonstrations: Showcasing successful applications by key customers in electric vehicles, energy storage systems, and other fields.

About EUBO

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000, is a national high-tech enterprise and one of the first “Specialized, Refined, Distinctive, and Innovative” (SRDI) companies, focusing on the research, development, and manufacturing of adhesives and lubricants. The company is headquartered in Shenzhen, operates a 30,000㎡ modern production base in Yichun, Jiangxi, and has branch offices across China.

EUBO has obtained multiple quality and management system certifications including ISO9001, IATF16949, and ISO14001. Its products are widely used in electronics, automotive, and new energy industries, serving over 1,000 global customers, including more than 30 Fortune Global 500 companies.

You are sincerely invited to visit Booth C308 and explore the future of electronic encapsulation materials with EUBO, discussing new opportunities in the era of green energy!