We sincerely thank all visitors to our booth. EUBO looks forward to further cooperation with you.

MESSAGE

AGIC + IOTE 2025, the 24th International Internet of Things Exhibition · Shenzhen, will grandly open from August 27–29, 2025, at the Shenzhen World Exhibition & Convention Center (Bao’an New Venue).

The exhibition will span 80,000 square meters, bringing together over 1,000 leading enterprises in the industry. With a focus on cutting-edge “AI + IoT” applications, it will cover multiple fields including smart cities, Industry 4.0, smart homes, smart logistics, smart hardware, and digital ecosystems, presenting a high-level intelligent event for the industry.

Shenzhen World Exhibition & Convention Center (Bao’an New Venue)

Hall 11, Booth 11B21

August 27–29, 2025

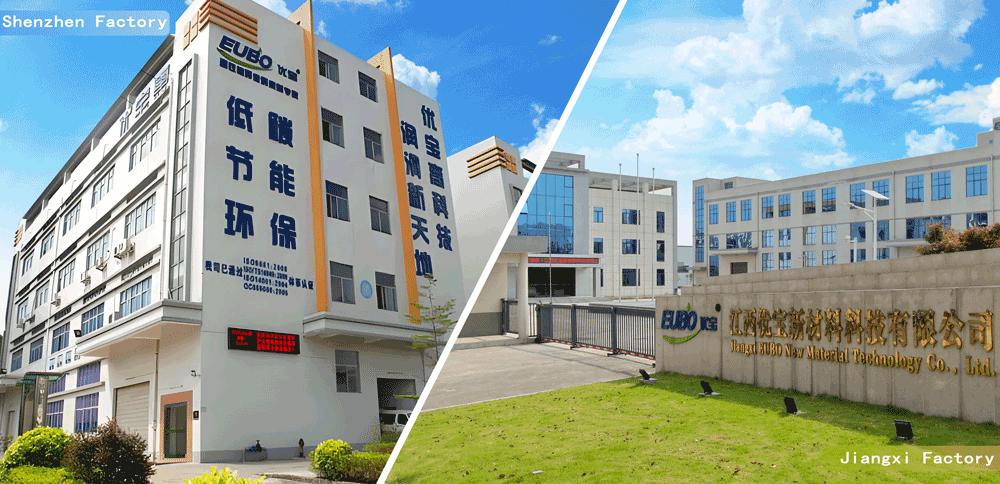

EUBO New Material Company Profile

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000 and headquartered in Shenzhen, operates a 30,000㎡ manufacturing base in Yichun, Jiangxi, and has branch offices in Shanghai, Fujian, Chongqing, and Hong Kong. As one of the first “Specialized, Refined, Distinctive, and Innovative” high-tech enterprises, the company has obtained certifications including ISO9001, IATF16949, ISO14001, and ISO45001. Its product portfolio covers electronic adhesives, lubricants, and functional protective materials, serving over 1,000 global customers, including more than 30 Fortune Global 500 companies.

EUBO Exhibit Highlights – Structural & Adhesive Solutions:

PUR hot melt adhesives, OLED module frame adhesives, epoxy adhesives, acrylic adhesives, and silicone adhesives. Some products are equipped with UV curing technology, enabling fast and precise positioning as well as efficient assembly.

Encapsulation & Protective Materials:

Conformal coating adhesives, potting adhesives, sealing adhesives, and nano water-repellent agents, providing comprehensive protection for electronic components.

Functional Adhesives:

Thermal conductive adhesives and electrically conductive adhesives, enhancing heat dissipation and electrical performance, supporting stable and efficient operation of smart devices.

You are cordially invited to visit EUBO New Material at Hall 11, Booth 11B21, Shenzhen World Exhibition & Convention Center (Bao’an New Venue) from August 27–29, 2025. We look forward to exploring industry trends and collaboration opportunities with you!

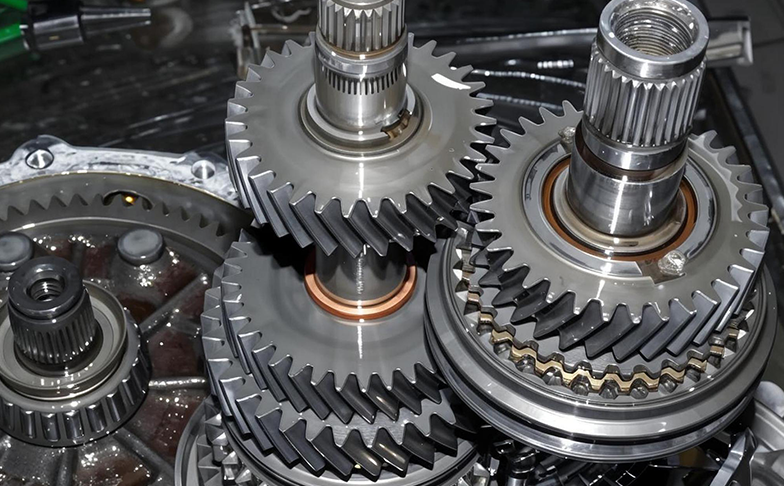

In motor design and operation, the reliability of the gear system directly affects overall performance and service life. Selecting the appropriate gear grease is a key factor in maintaining proper gear transmission and reducing failures. Its main benefits include the following aspects:

Firstly, gear grease can effectively enhance the fatigue resistance of gear surfaces. By forming a firmly adsorbed lubricating film on the meshing teeth, it reduces direct metal-to-metal contact, thereby mitigating micro-pitting and macroscopic fatigue flaking caused by cyclic stress.

Secondly, gear grease provides excellent vibration damping and noise reduction. Its internal dispersion structure and thickener system absorb and dissipate impacts and vibrations generated during gear transmission, helping to improve operational smoothness and reduce noise emissions.

In addition, gear grease significantly reduces gear surface wear. During the relative motion of gear pairs, the base oil in the grease forms a separating film at the contact area, preventing dry friction, controlling abrasive and adhesive wear, and extending the service life of components.

Particularly under high-load or high-temperature conditions, gear grease can prevent gear surface welding. Through the use of specialized additive packages, it maintains oil film strength at elevated temperatures, preventing localized micro-welding and material transfer, ensuring that gear pairs operate reliably under demanding conditions.

In summary, gear grease plays a critical role in lubricating and protecting motor gear systems. Selecting a grease with performance characteristics matched to the application can significantly improve transmission efficiency, extend maintenance intervals, and reduce failure risks, which is vital for the overall reliability and service life of motors.

For further guidance on selecting gear grease and technical solutions tailored to specific motor types, please contact EUBO New Materials. We provide professional support and expertise.

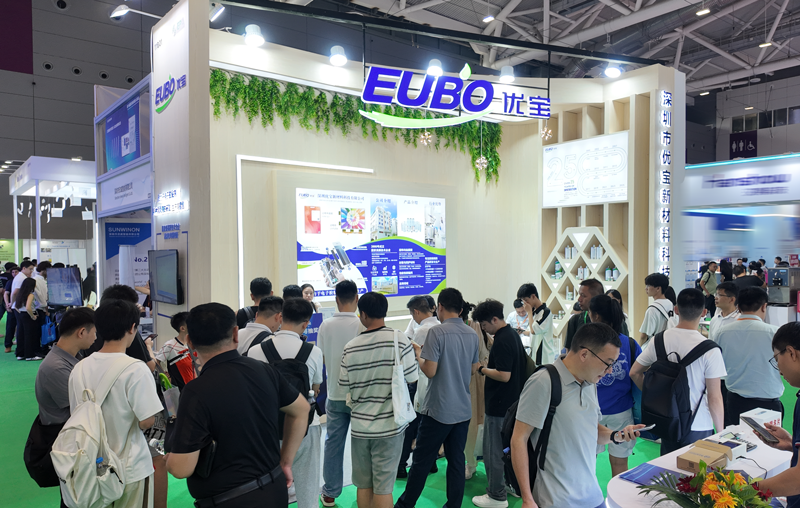

From August 27 to 29, 2025, IOTE 2025, the 24th International Internet of Things Expo, successfully concluded at the Shenzhen World Exhibition & Convention Center. As a major event in the IoT industry, the expo gathered over 1,000 companies and more than 100,000 professional visitors. EUBO New Materials showcased its innovative electronic adhesives and lubricants in Hall 11’s e-paper ecosystem area, demonstrating its technological applications in e-paper, OLED screen bonding, and electronic packaging.

At EUBO’s booth, multiple adhesives specifically designed for e-paper bezels and OLED display edge sealing were showcased, including PUR hot-melt adhesives, OLED module frame adhesives, and UV adhesives. All products utilize advanced UV curing technology, ensuring enhanced bonding strength while achieving fast, precise positioning and efficient assembly.

In addition, to enhance the durability and stability of electronic devices, we showcased protective encapsulation materials such as conformal coating adhesives, potting adhesives, sealing adhesives, and nano waterproofing agents. These materials effectively protect devices from external factors like moisture and dust, ensuring long-term stable operation.

In the field of functional adhesives, EUBO showcased thermally conductive and electrically conductive adhesives specifically designed for smart devices. These adhesives optimize heat dissipation, enhance electrical stability, and meet the modern electronics industry’s demands for efficient thermal management and electrical isolation.

This exhibition provided EUBO with significant brand exposure and market expansion opportunities. The booth attracted a large number of industry professionals, creating a lively atmosphere for technical exchanges and earning widespread industry attention and recognition. Looking ahead, EUBO will continue to focus on product and technological innovation, delivering more efficient and reliable solutions to its customers. We look forward to collaborating with more industry partners to jointly drive the development of smart devices and electronic products.

We sincerely thank all visitors to our booth. EUBO looks forward to further cooperation with you.

With the continuous advancement of automotive technology, especially the development of new energy vehicles, automotive interior design is increasingly shifting toward intelligent and entertainment-focused features. Displays, particularly large touchscreens, have become standard in modern vehicles, widely used for in-car entertainment, navigation, and climate control systems. To meet these demands, EUBO provides professional PUR hot-melt adhesive solutions, ensuring the stability and safety of displays during long-term use.

Automotive interior displays operate in complex environments and must withstand extreme temperature fluctuations, humidity, and vibrations during driving. Therefore, selecting high-performance adhesive materials is critical to ensure the durability and safety of the display, guaranteeing stable performance under all conditions.

In the manufacturing process, PUR hot-melt adhesive is mainly used to bond the display to its housing and support structures. Considering that displays are exposed to harsh conditions such as high and low temperatures and constant vibration, EUBO has specially developed the UR 6132 hot-melt adhesive with strong bonding strength and long-lasting durability to meet these demands. By precisely controlling the distribution of adhesive dots, the UR 6132 ensures uniform and secure bonding. Additionally, its fast-curing properties significantly improve production efficiency, reduce waiting time, and optimize the manufacturing process.

Advantages of EUBO UR 6132 Hot-Melt Adhesive:

1. Strong Bonding:

Achieves rapid and strong adhesion, providing stable bonding performance for long-term use.

2. High and Low Temperature Resistance:

Maintains stability under extreme temperatures, adapting to the temperature variations inside and outside the vehicle.

3. Vibration and Weather Resistance:

Excellent vibration resistance and durability, effectively withstanding shocks and long-term usage.

4. Fast Curing:

The hot-melt adhesive accelerates the curing process, shortening production cycles and improving manufacturing efficiency.

5. Environmentally Friendly and Non-Polluting:

100% solid content, solvent-free, compliant with global environmental standards, ensuring in-car air quality.

Currently, EUBO PUR hot-melt adhesives are widely used in the production of automotive interior displays. Thanks to their excellent bonding performance, high-temperature resistance, and vibration durability, they have become the preferred solution for many well-known automakers. With the ongoing advancement of automotive intelligence and electrification, EUBO PUR hot-melt adhesives will continue to be optimized to meet the growing industry demand for high-performance bonding materials, driving continuous innovation and development in automotive interior displays.

With the continuous development of consumer electronics, TWS Bluetooth earphones have become mainstream in the market due to their lightweight and wireless advantages. In the design and manufacturing of TWS Bluetooth earphones, adhesives play a critical role. EUBO’s PUR hot-melt adhesive provides efficient bonding, sealing, and protection for various components of the earphones, meeting the requirements for miniaturization, precision, and high performance.

TWS Bluetooth Earphone Bonding Solution

EUBO’s UR 6140 hot-melt adhesive solution is specifically designed for TWS Bluetooth earphones, capable of meeting the demands of their complex structures. Particularly for small components such as earphone screens, high precision and consistency of the adhesive are critical. UR 6140 offers excellent initial bonding strength, high-temperature resistance, and chemical stability, ensuring the earphones remain reliable under various conditions. Its environmentally friendly formula, 100% solid content, and solvent-free characteristics comply with international environmental standards while ensuring safety during the manufacturing process.

UR6140 Hot-Melt Adhesive Applications

UR 6140 hot-melt adhesive is widely used in multiple key components of TWS Bluetooth earphones, including the front housing of the earphone cavity, charging contact modules, speaker module FPC fixation, and battery securing. Through precise dispensing processes, UR 6140 provides stable bonding strength while offering excellent water- and dust-resistant properties, significantly enhancing the earphones’ sealing performance and durability.

Features of EUBO UR 6140 Adhesive

High Initial Bonding Strength:

Rapidly forms a strong bond, allowing for short or even no pressure curing.

Cold and Humidity Resistance:

Maintains excellent performance under extreme temperature and humidity, ensuring earphone stability in various climates.

Water and Sweat Resistance:

Ideal for earphones and other consumer electronics, effectively resisting moisture and sweat.

Excellent Adhesion:

Provides strong bonding across multiple substrates, ensuring the stability of earphone components.

Weather and Chemical Resistance:

Retains outstanding adhesion even in harsh conditions such as humidity, sweat, and salt spray.

100% Solid Content, Solvent-Free:

Environmentally friendly and safe, compliant with international environmental standards.

EUBO provides TWS Bluetooth earphone manufacturers with efficient and reliable PUR hot-melt adhesive solutions, helping earphones achieve optimal performance in precision structure, lightweight design, and durability, meeting the market demand for high-quality Bluetooth earphones.

Nowadays, many machinery and instruments require water, moisture, and corrosion resistance to achieve longer service life. Dry film oil has become a widely used lubricant in the industry, capable of meeting these consumer demands. Dry film oil is a specially formulated, clean, dry-film lubricant. After drying, this fast-drying lubricant forms a transparent, dry, and non-sticky lubricating coating on the surface of the workpiece. Below, we explore the performance features of dry film oil together with the technical experts from EUBO.

Dry Film Oil

Versatile Surface Penetration and Bonding

Dry film oil can penetrate and bond to surfaces of metals, paper, wood, rubber, plastics, glass, and most other components requiring lubrication. It forms a non-sticky lubricating film that prevents direct contact between friction surfaces, thereby reducing wear.

Excellent Wear Resistance and High-Temperature Performance

Offers outstanding wear resistance, water resistance, and acid/base wash resistance, and can withstand temperatures up to 380°C.

Non-Flowing and Dust-Resistant Film

The coating does not flow, does not attract dust or dirt particles, is non-flammable, odorless, and highly safe.

Excellent Thermal and Chemical Stability

When applied to electronic components, it can naturally form an insulating layer. For parts where oils or other lubricants cause contamination, curing, or viscosity changes that prevent proper lubrication, dry film lubricants are the ideal solution.

Additional Key Features

Resistant to dust, low torque, suitable for high and low temperatures, non-oily, noise-reducing, and addresses issues such as diffusion and contamination associated with traditional oil-based lubricants.

In addition to the points mentioned above, dry film oil possesses many other performance advantages that are not listed here. For further information, please contact our consultation hotline, where our professional staff can provide detailed explanations. We hope this sharing helps you gain a better understanding!