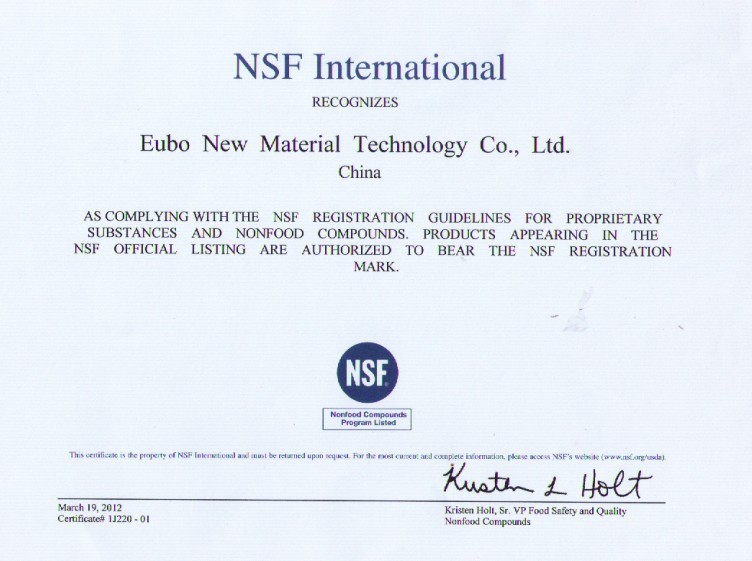

Recently, one of the most authoritative certification bodies in the food processing industry—the NSF (National Sanitation Foundation, USA)—awarded EUBO a plaque recognizing“20 Consecutive Years of NSF International Certification”. EUBO is also among the first domestic companies to achieve NSF certification for 20 consecutive years. This honor not only acknowledges EUBO’s consistent strength in the design, production, and quality management of food-grade lubricants over the past two decades but also serves as a strong support for its continued development in the future.

20 Consecutive Years of NSF International Certification

EUBO’s ability to maintain NSF certification for 20 consecutive years is the result of its continuous investment in product quality and rigorous control standards. NSF food-grade certification indicates that EUBO lubricants comply with the FDA’s food-grade requirements, making them suitable for use in equipment that comes into contact with food, thereby ensuring food safety and hygiene.

EUBO’s lubricants not only comply with FDA regulations but have also obtained international certifications includingROHS, REACH, 23P, Halogen-Free, and EN71-3. All products come withSafety Data Sheets (MSDS)and relevant test reports, ensuring that they are green, environmentally friendly, energy-saving, and low-carbon. Behind these certifications lies EUBO’s rigorous control and continuous improvement across every stage ofproduct R&D, production, and testing.

The Significance of NSF Certification

NSF is a globally leading public health and safety organization, dedicated to developing and promoting standards for product hygiene, safety, and quality. Worldwide, NSF certification is recognized as a mark of high quality, environmental friendliness, and safety. It holds particular importance in thefood, beverage, pharmaceutical, and industrial lubricant sectors. NSF certification covers multiple aspects includingproduction processes, management systems, product formulations, and testing, imposing strict requirements on manufacturing procedures, product quality, safety, and environmental impact.

High Requirements and Challenges of NSF Certification

Obtaining NSF certification is no easy task. It requires companies to conduct strict self-audits and improvements across multiple dimensions to meet high international standards. Specifically, NSF certification involves, but is not limited to, the following aspects:

01. Safety of Raw Materials and Formulations

All raw materials used in production must comply with safety standards and undergo rigorous testing and verification.

02. Strict Control of the Production Process

The production process must meet NSF hygiene and safety requirements, including equipment cleanliness and controlled production environments.

03. Verification of Product Performance

Products must pass multiple performance tests to ensure they meet the intended functional requirements.

04. Continuous Quality Monitoring and Improvement

Companies are required to submit product samples regularly to NSF and have them verified by third-party testing agencies to ensure products consistently meet quality standards.

Due to these stringent requirements, obtaining and maintaining NSF certification is a significant challenge. Companies must achieve high standards in both technology and management while maintaining continuous investment and improvement to ensure their products always comply with strict NSF certification criteria.

Looking Ahead

Receiving NSF international certification for 20 consecutive years is both an honor and a responsibility for EUBO. The company will continue to uphold principles of integrity, innovation, and compliance, strictly following NSF certification requirements and relevant regulations, while dedicating itself to the research, development, and production of food-grade lubricants. Adhering to the principle of “Quality First, Customer Foremost,” EUBO will continuously enhance product quality and safety, striving to provide customers with superior, reliable products and services.

Currently, EUBO’s food-grade lubricants are widely used in various food production equipment, food processing, medical devices, and drinking water applications. The company will continue to invest in technological research and innovation to improve product performance and market competitiveness. Looking to the future, EUBO will maintain a quality- and efficiency-driven development path, steadily enhancing its core competitiveness and brand influence, providing domestic and international customers with high-quality products and services, and jointly promoting the healthy and sustainable development of the industry.

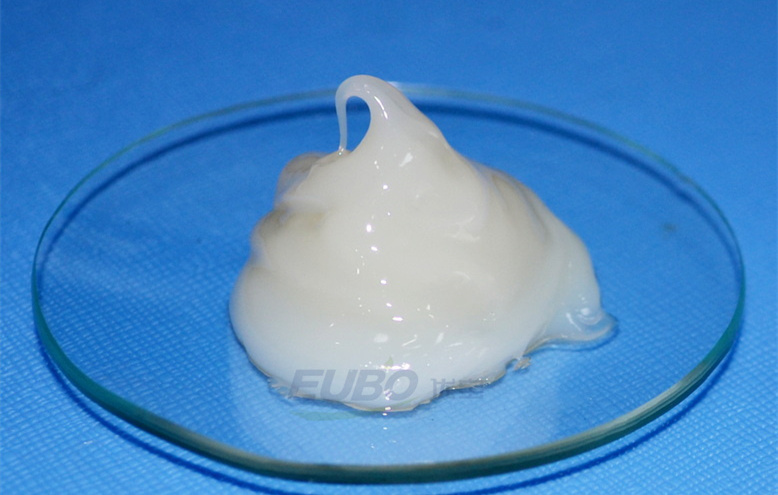

Damping grease is a functional grease made from specially selected polymers, specialty additives, and thickeners through a unique manufacturing process. It features excellent adhesion, high viscosity, superior lubrication performance, chemical stability, and mechanical stability. It is particularly suitable for positions between plastics and metals that require long-term damping (buffering, resistance) and lubrication.

Typical application areas of damping grease include:

Sealing and leak-prevention parts: Such as sealing valves in water or fuel gates, used for lubrication and leak-proof filling.

Precision instruments: Parts that require damping and buffering.

Household products: Items that need cushioning or a naturally comfortable tactile feel.

Hardware and power tools: High-end door hinges, faucets, power tools, and movable joints in plastic toys.

Office equipment and mechanical structures: Internal plastic or metal moving parts in office equipment, toys, gearboxes, etc., requiring lubrication, noise reduction, shock absorption, or resistance functions.

Special application case: High-end door hinges.

Over the past two decades, high-end door hinges—typically made of premium stainless steel or brass—have widely adopted fully synthetic damping grease, originally used for protecting optical and automotive components, as their core lubrication material. The grease is injected into the hinge pivot before leaving the factory, offering significant advantages:

Excellent adhesion: Minimizes grease loss.

Superior lubrication and corrosion protection: Extends the service life of the hinge.

Long-lasting noise reduction and damping: Ensures smooth, quiet opening and closing with an appropriate resistance for tactile feedback.

Important note: Temperature effect on viscosity

The viscosity of damping grease varies with temperature: it decreases at high temperatures and increases at low temperatures. Therefore, when selecting damping grease:

Always choose viscosity according to the actual operating temperature range.

For high-temperature environments requiring stable viscosity, select products with excellent high-temperature performance and a high viscosity index.

PUR Hot Melt Adhesive (Moisture-Curing Polyurethane Hot Melt Adhesive) has become the preferred solution for bonding, protection, and assembly in the electronics industry due to its excellent performance. It is a 100% solid, solvent-free, and non-toxic adhesive, notable for its rapid curing: solid at room temperature, it melts upon heating for application, achieves quick initial tack upon cooling under pressure, and then completes final curing through reaction with ambient moisture.

Unique Curing Mechanism:

Applied in a molten state, it achieves initial adhesion upon cooling and forms high-strength polymers through moisture curing, significantly enhancing final bonding strength, heat resistance, and low-temperature performance.

Irreversibility:

Unlike most reversible conventional hot melts, PUR adhesive becomes irreversible after moisture curing (does not remelt upon reheating), providing superior high- and low-temperature durability.

Outstanding Electronic Applications:

High Bonding Strength: Achieves strong adhesion after curing, meeting the requirements of most electronic products.

Precision Application: Excellent control over bead size, ideal for narrow frames and fine-feature designs.

Reworkability: As a thermoplastic polyurethane, bonded components are relatively easier to disassemble for repair.

Environmentally Friendly and Safe:

Solvent-free and compliant with environmental standards.

Thanks to the above advantages, PUR hot melt adhesive is widely used in various stages of electronic product manufacturing, including:

Screen assembly and component bonding for smartphones, tablets, learning devices, GPS navigators, and wearable devices.

Window bonding and housing structure adhesion.

Battery fixation.

Flat surface sealing.

PCB assembly and protection.

After production, it is essential to thoroughly clean the adhesive rollers to prevent residual glue from curing and affecting subsequent production or product quality.

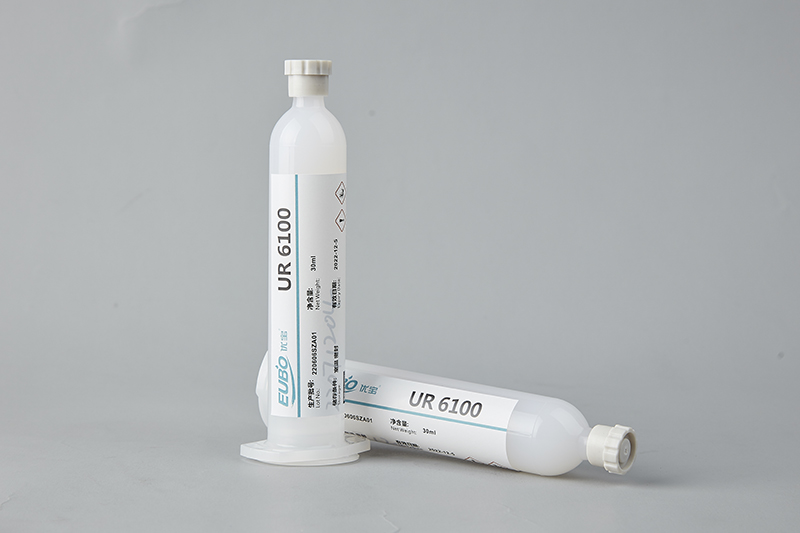

EUBO PUR Hot Melt Adhesive:

EUBO’s PUR hot melt adhesive is a general-purpose, single-component, moisture-curing hot melt with good initial tack at room temperature. From a performance perspective, we focus on enhancing PUR hot melt properties—such as viscosity, melting temperature, melt viscosity, and initial tack. Choosing the right adhesive is therefore a solid first step toward optimal results.

Low-Temperature Damping Grease is specially designed for precision mechanisms operating under high and low temperature conditions (-20℃ to 80℃). Its core advantage lies in maintaining stable torque across a wide temperature range, ensuring effective damping and shock absorption for precision positioning mechanisms, fine-tuning devices, and stiction/ buffering components. This allows moving parts to operate smoothly, gently, and accurately.

Typical Applications Include:

Damping and anti-slip mechanisms for lens focusing in cameras, microscopes, telescopes, and rangefinders

Turntable damping gears and switch devices in disc players

Other precision mechanical components requiring stable damping performance at low temperatures

To ensure optimal performance and safe use, please strictly follow these precautions:

Clean and Dry: Before application, ensure that the area to be greased is completely dry, clean, and free of contamination.

Prevent Contamination: During use and storage, strictly prevent dust and foreign particles from mixing in. Always tightly seal the container after use.

No Mixing: Do not mix with other types of greases, as this may cause adverse reactions, reduce performance, or damage components.

Plastic Compatibility: For special plastic parts, conduct a compatibility test or obtain explicit approval from the plastic manufacturer before use to avoid swelling, embrittlement, or other adverse effects.

Proper Storage: Store the product in a clean, dry, cool, and dark place.

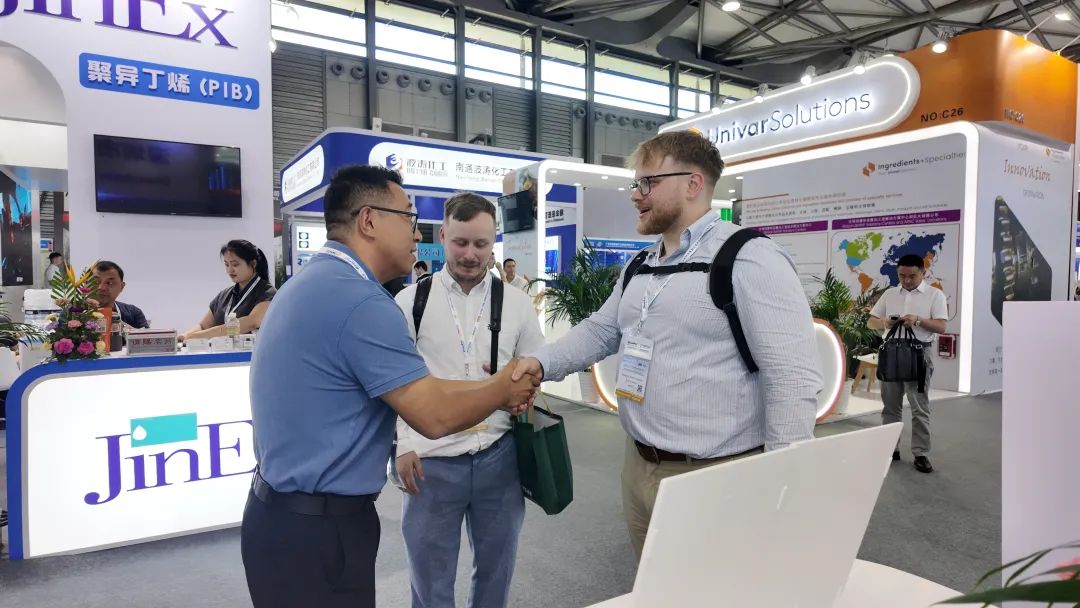

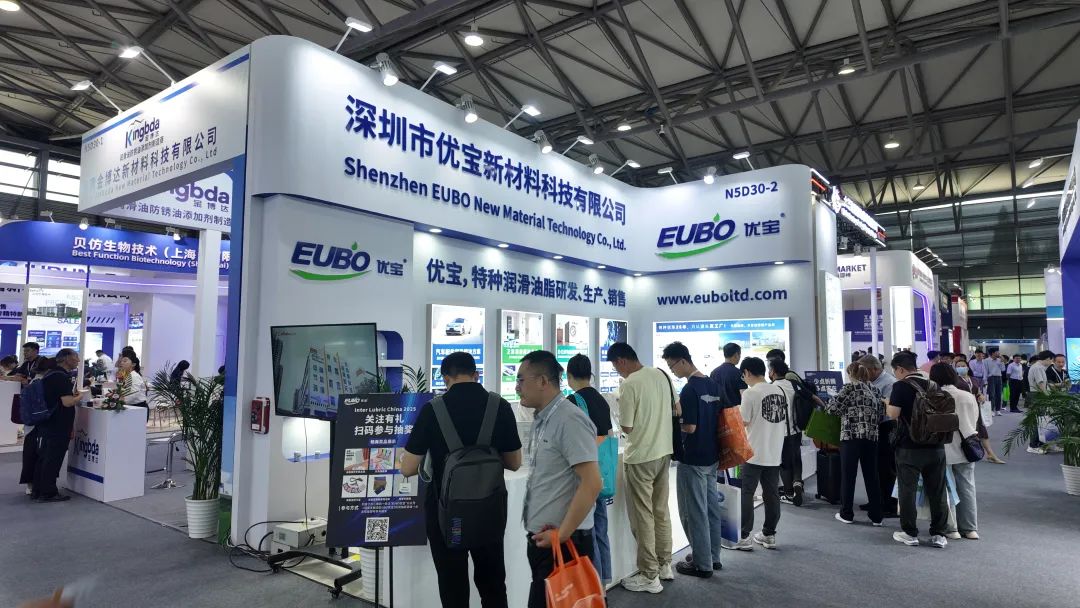

From June 4 to 6, 2025, the 24th Shanghai International Lubricants and Application Technology Expo, together with the Shanghai International Metalworking Fluids and Surface Cleaning Technology Expo, was grandly held in Shanghai. As a leading company in China’s new materials sector, Shenzhen EUBO New Material Technology Co., Ltd. showcased numerous innovative products and technologies, attracting widespread attention from professionals both within and outside the industry.

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000 and headquartered in Guangming District, Shenzhen, is a high-tech enterprise specializing in the research, development, and production of new materials, including lubricants, adhesives, and protective coatings. Leveraging its outstanding technological strength and innovative capabilities, the company has been recognized as one of the first “Specialized, Refined, Distinctive, and Innovative” (专精特新) enterprises in Shenzhen. EUBO has established a 30,000㎡ production base in Yichun, Jiangxi, and operates branch offices in Shanghai, Fujian, Chongqing, Hong Kong, and other locations, with a broad business reach.

At this expo, EUBO New Material showcased its cutting-edge technologies and innovative products in the fields of lubricants, protective materials, and adhesives. The company’s specially developed greases are designed for extreme conditions, including high speed, heavy load, high or low temperatures, low noise, water resistance, sealing, corrosion protection, and lubrication, demonstrating EUBO’s deep technical expertise in specialty grease development. In addition, EUBO’s adhesive product portfolio covers module edge-bonding adhesives, UV-curable adhesives, structural adhesives, bottom-filling adhesives, PUR hot-melt adhesives, coating adhesives, and nano water-repellent agents. These products are widely applied across electronics, automotive, and machinery industries, providing customized solutions for clients in diverse sectors.

EUBO New Material has obtained certifications for ISO9001, IATF16949, and QC080000 quality management systems, ISO14001 environmental management system, and ISO45001 occupational health and safety management system. These certifications signify that the company has achieved internationally advanced standards in quality management, environmental protection, and occupational health and safety. Leveraging its excellent product quality and comprehensive management systems, EUBO New Material has gained strong market recognition and received numerous honors, including being a standing director unit of the Shenzhen New Materials Industry Association, one of China’s Top 100 Innovative SMEs, and one of Shenzhen’s Top 100 Independently Innovative SMEs.

With high-quality products and services, the company has earned the trust of over 1,000 global clients, including more than 30 Fortune 500 companies. At this expo, EUBO’s booth attracted significant attention from domestic and international visitors, who expressed strong interest in the company’s products and technologies and engaged in in-depth discussions with company representatives to explore potential cooperation opportunities.

EUBO New Material’s R&D Engineering Center has been recognized by the Provincial Department of Science and Technology as the “Guangdong Provincial Engineering Technology Research Center for Advanced Lubrication and Protective Materials” and also serves as a Postdoctoral Innovation and Practice Base in Shenzhen. The company has established long-term and stable technical collaborations with multiple research institutions, including the Shenzhen Tsinghua University Research Institute, Southern University of Science and Technology, and the Institute of Chemistry, Chinese Academy of Sciences. Its R&D team consists of over 30 professionals, including local leading talents of Shenzhen, reserve talents, postdoctoral researchers, senior engineers, and experienced R&D engineers, demonstrating strong capabilities in scientific research, product development, and technological innovation.

The center houses multiple specialized laboratories, including an Advanced Materials Laboratory, Pilot Production Base, Precision Instrument Room, Reliability Laboratory, Physical and Chemical Laboratory, and Test Bench Laboratory, equipped with over 100 professional new material testing and analysis instruments, capable of handling more than 200 testing projects. At this expo, EUBO New Material showcased its advanced R&D equipment and testing capabilities, highlighting the company’s strong strengths in technological innovation and product quality control.

Shenzhen EUBO New Material Technology Co., Ltd.’s impressive presence at the 2025 Shanghai International Lubricants and Application Technology Expo and the Shanghai International Metalworking Fluids and Surface Cleaning Technology Expo fully demonstrated its robust capabilities and innovative spirit as an industry leader. Looking ahead, EUBO New Material will continue to increase R&D investment, deepen collaborations with research institutions, and continuously enhance product performance and service quality, providing global clients with superior new material solutions and driving industry development and progress.

1. Anti-Wear Performance Test (SH/T 0204)

Using a specialized anti-wear testing device, under a specified load, the upper steel ball rotates relative to three stationary steel balls on the lower surface, which are coated with the grease sample. After the test, the wear scar diameters on the three lower steel balls are measured. The size of the wear scars is used to evaluate the anti-wear performance of the grease.

2. Four-Ball Test Method (GB/T 3142)

In the four-ball test, grease is applied to a ball cup, and under a specified load, the upper bearing steel ball rotates at a set speed against three stationary steel balls below. After a period of operation, the wear scar diameters are measured to evaluate the extreme pressure (EP) performance of the grease.

There are three common expressions for this method: PB value, PD value, and ZMZ value:

PB value: The maximum load under which no seizure occurs during the test, expressed in Newtons (N).

PD value: The minimum load at which the rotating ball and the three fixed balls weld under the test conditions, expressed in N.

ZMZ value: An indicator of the grease’s resistance to extreme pressure under applied loads. During the test, the load is incrementally applied to the three stationary balls in 0.1 logarithmic units, and the first ten seizure load results are used to calculate the ZMZ value, expressed in N.

3. Timken Test

This test is performed using a Timken test machine. Grease is applied between the friction surfaces of a metal ring and steel block under a specified load and speed. After a period of operation, the wear marks on the metal balls are examined to determine the EP performance of the grease, represented by the OK value.

Purpose: To analyze the grease’s ability to resist loads under line contact.

Test Method: SH/T 0203

4. Four-Ball Extreme Pressure Test (GB/T 12583)

This method is also expressed using three indicators: PB value, PD value, and LWI value.

LWI value: Indicates the extreme pressure capacity of a sealed grease under a limiting load. It is determined by applying incremental loads in 0.1 logarithmic units on the three stationary balls and performing ten tests before the seizure point. The average corrected load represents the LWI value.