PUR Hot Melt Adhesive (Moisture-Curing Polyurethane Hot Melt Adhesive) has become the preferred solution for bonding, protection, and assembly in the electronics industry due to its excellent performance. It is a 100% solid, solvent-free, and non-toxic adhesive, notable for its rapid curing: solid at room temperature, it melts upon heating for application, achieves quick initial tack upon cooling under pressure, and then completes final curing through reaction with ambient moisture.

Unique Curing Mechanism:

Applied in a molten state, it achieves initial adhesion upon cooling and forms high-strength polymers through moisture curing, significantly enhancing final bonding strength, heat resistance, and low-temperature performance.

Irreversibility:

Unlike most reversible conventional hot melts, PUR adhesive becomes irreversible after moisture curing (does not remelt upon reheating), providing superior high- and low-temperature durability.

Outstanding Electronic Applications:

High Bonding Strength: Achieves strong adhesion after curing, meeting the requirements of most electronic products.

Precision Application: Excellent control over bead size, ideal for narrow frames and fine-feature designs.

Reworkability: As a thermoplastic polyurethane, bonded components are relatively easier to disassemble for repair.

Environmentally Friendly and Safe:

Solvent-free and compliant with environmental standards.

Thanks to the above advantages, PUR hot melt adhesive is widely used in various stages of electronic product manufacturing, including:

Screen assembly and component bonding for smartphones, tablets, learning devices, GPS navigators, and wearable devices.

Window bonding and housing structure adhesion.

Battery fixation.

Flat surface sealing.

PCB assembly and protection.

After production, it is essential to thoroughly clean the adhesive rollers to prevent residual glue from curing and affecting subsequent production or product quality.

EUBO PUR Hot Melt Adhesive:

EUBO’s PUR hot melt adhesive is a general-purpose, single-component, moisture-curing hot melt with good initial tack at room temperature. From a performance perspective, we focus on enhancing PUR hot melt properties—such as viscosity, melting temperature, melt viscosity, and initial tack. Choosing the right adhesive is therefore a solid first step toward optimal results.

EUBO PUR Hot Melt Adhesive is a versatile, single-component reactive hot melt adhesive. It exhibits excellent initial tack at room temperature and shows outstanding compatibility with a wide range of substrates, including plastics, metals, ceramics, and inorganic glass, quickly achieving positioning strength in a short time.

This product is especially suitable for bonding frames and display screen bezels in various consumer electronics, particularly for adhesion between metal frames and plastic parts. Its fast curing and high initial tack provide significant pressure-free bonding benefits (eliminating the need for traditional pressing steps), while maintaining pressure-sensitive characteristics for approximately 10 minutes after dispensing, facilitating easy positioning and handling.

Single-component, Solvent-free: Convenient to use, environmentally friendly, and safe.

Enhanced Production Efficiency: Shortens assembly time, improving efficiency, throughput, and product yield.

Excellent Mechanical Performance: After curing, the adhesive forms a tough matrix, providing outstanding drop-resistance for the final product.

High Bonding Efficiency: Strong initial tack and high final bonding strength, reducing adhesive consumption.

EUBO PUR Hot Melt Adhesive is widely used in the electronics industry, including but not limited to:

Smartphones and tablet screen assembly

Educational devices (learning machines)

GPS navigation devices

Wearable electronics (window bonding, casing structural bonding)

Battery bonding and fixation

Planar sealing

PCB assembly and protection

Post-dispensing Cleanup: Wait until the adhesive cools to room temperature, then remove any excess adhesive that has overflowed at the edges.

Uncured Adhesive Removal: Any remaining uncured adhesive can be scraped off using a blade.

Solvent Wiping: If wiping is necessary at the dispensing site, common cleaning solvents such as toluene or acetone can be used.

Timely Cleaning: Ensure adhesive residues are removed before the adhesive is fully cured.

Heating and Usage Duration: Do not repeatedly heat the adhesive. Once opened, it must be used within 8 hours. Continuous single-time heating should not exceed 8 hours.

Temperature Control: The operating temperature should not be set too high and must be ≤ 130°C to prevent the risk of tube rupture under high temperature and pressure.

Safety Protection: Take care to avoid burns during operation.

Storage Conditions: Store the product in a dry environment with a temperature between 15–25°C.

Packaging Requirements: The product should be kept in vacuum-sealed aluminum foil bags.

Shelf Life: Under the above storage conditions and unopened, the product has a shelf life of 6 months.

Potting adhesives are indispensable materials in the electronics industry, playing a key role in ensuring the safety, reliability, and longevity of electronic products. Their necessity can be highlighted in the following aspects:

Enhanced Protection and Structural Strength:

Physical Protection: After curing, potting adhesives form a protective layer that significantly enhances the overall structural strength of electronic components, improving resistance to external impacts, vibrations, and mechanical stresses.

Environmental Sealing: They effectively prevent direct exposure of internal components and circuits, providing excellent barriers against water, moisture, dust, and corrosion, thus protecting delicate circuitry from harsh environments.

Improved Electrical Performance and Miniaturization:

Reliable Insulation: Potting adhesives greatly enhance insulation between specialized internal components and complex circuits, preventing short circuits and leakage, ensuring safe operation of the device.

Facilitates Miniaturization: The filling and protection provided by potting adhesives help secure micro-components, supporting lightweight and compact design in electronic products.

Addressing Thermal Challenges:

Modern electronic products feature high precision and high power density, which can easily lead to excessive component temperatures, causing failures and shortening product lifespan.

Potting adhesives—especially thermally conductive types—act as a critical thermal management medium. When applied inside electronic products, they efficiently transfer heat generated by internal components to the casing, significantly improving overall heat dissipation performance.

Ensuring Comprehensive Performance:

High-quality potting adhesives not only provide excellent shock resistance, sealing, and thermal conductivity after curing, but also offer good heat resistance, flame retardancy, weatherability (resistance to thermal cycling, UV, etc.), and long-term stability.

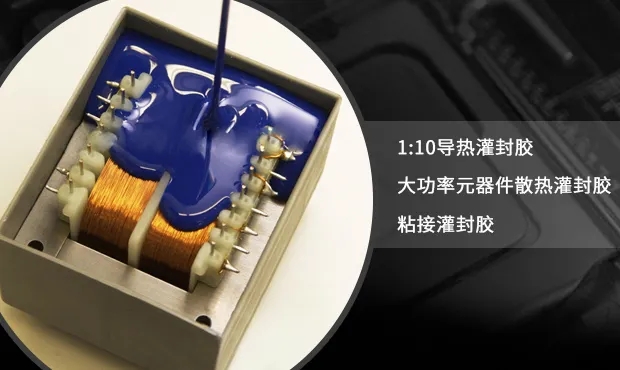

EUBO potting adhesives are designed to meet the needs of electronic products, providing the following key functions:

Structural Reinforcement & Impact Resistance:

Forms a tough protective layer after curing, enhancing the overall structural strength of electronic devices and effectively resisting external impacts and vibrations.

Electrical Insulation & Miniaturization Support:

Significantly improves insulation between internal components and circuits, ensuring electrical safety. Its filling properties also support miniaturization and lightweight design of devices.

Comprehensive Environmental Protection:

Prevents sensitive components and circuits from direct exposure, providing excellent protection against water, moisture, dust, and corrosion.

Multifunctional Performance Assurance:

Once fully cured, the adhesive offers thermal conductivity, flame retardancy, high/low temperature resistance, dust protection, and circuit shielding, ensuring the safe and stable operation of electronic components.

In addition to the core functions, EUBO potting adhesives feature excellent processing and usage characteristics:

Excellent Processability: Low viscosity and strong penetration during potting, fully filling fine gaps and encapsulating components.

High Stability: Components are stable, easy to store, and have a long shelf life, suitable for large-scale automated production lines.

Superior Curing Performance: Minimal filler sedimentation during curing, low risk of phase separation, ensuring uniform and consistent performance.

Outstanding Comprehensive Properties: After curing, exhibits excellent flame retardancy, weatherability, thermal conductivity, resistance to high/low temperature cycles, and water resistance.

EUBO potting adhesives are widely used in electronic components requiring protection, insulation, and thermal management, including but not limited to:

Power & Drive: Transformers, high-voltage packs, rectifiers, filters, drivers, igniters, ignition coils, power controllers, aquarium pumps, energy-saving modules.

Lighting: LED lighting, LED barrier lights, LED modules.

Security & Sensing: Electronic locks, magnetic locks, electronic sensing modules.

Automotive Electronics: Xenon lamps, light boosters.

Others: Capacitors, negative ion generators, etc.

Application Benefits: Provides reliable potting and filling, circuit shielding, electrical insulation, and moisture/water protection for the above components.

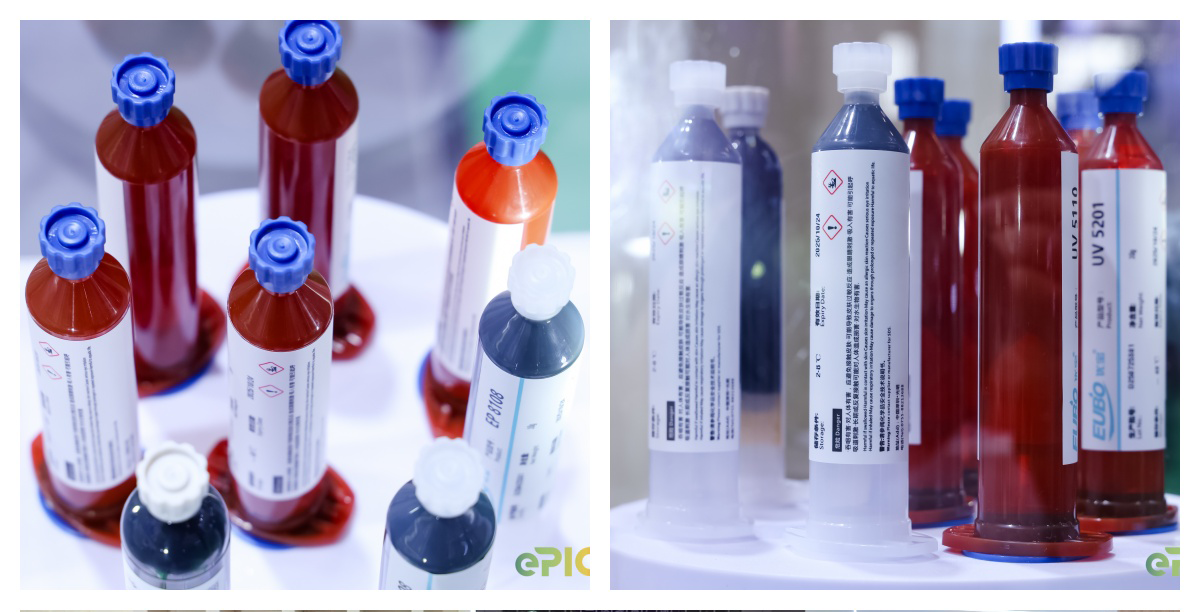

EUBO offers a comprehensive range of electronic adhesive products to meet diverse needs, including:

Potting adhesives

PUR hot melt adhesives

Module frame adhesives

Underfill adhesives

Two-component structural adhesives

Coating adhesives

Thermally conductive adhesives

Sealing adhesives

These products are widely applied to various electronic components, ensuring product safety, long-term reliability, and environmental compliance.

Contact EUBO today to obtain professional and reliable electronic adhesive solutions!

With the continuous advancement of automotive technology, especially the development of new energy vehicles, automotive interior design is increasingly shifting toward intelligent and entertainment-focused features. Displays, particularly large touchscreens, have become standard in modern vehicles, widely used for in-car entertainment, navigation, and climate control systems. To meet these demands, EUBO provides professional PUR hot-melt adhesive solutions, ensuring the stability and safety of displays during long-term use.

Automotive interior displays operate in complex environments and must withstand extreme temperature fluctuations, humidity, and vibrations during driving. Therefore, selecting high-performance adhesive materials is critical to ensure the durability and safety of the display, guaranteeing stable performance under all conditions.

In the manufacturing process, PUR hot-melt adhesive is mainly used to bond the display to its housing and support structures. Considering that displays are exposed to harsh conditions such as high and low temperatures and constant vibration, EUBO has specially developed the UR 6132 hot-melt adhesive with strong bonding strength and long-lasting durability to meet these demands. By precisely controlling the distribution of adhesive dots, the UR 6132 ensures uniform and secure bonding. Additionally, its fast-curing properties significantly improve production efficiency, reduce waiting time, and optimize the manufacturing process.

Advantages of EUBO UR 6132 Hot-Melt Adhesive:

1. Strong Bonding:

Achieves rapid and strong adhesion, providing stable bonding performance for long-term use.

2. High and Low Temperature Resistance:

Maintains stability under extreme temperatures, adapting to the temperature variations inside and outside the vehicle.

3. Vibration and Weather Resistance:

Excellent vibration resistance and durability, effectively withstanding shocks and long-term usage.

4. Fast Curing:

The hot-melt adhesive accelerates the curing process, shortening production cycles and improving manufacturing efficiency.

5. Environmentally Friendly and Non-Polluting:

100% solid content, solvent-free, compliant with global environmental standards, ensuring in-car air quality.

Currently, EUBO PUR hot-melt adhesives are widely used in the production of automotive interior displays. Thanks to their excellent bonding performance, high-temperature resistance, and vibration durability, they have become the preferred solution for many well-known automakers. With the ongoing advancement of automotive intelligence and electrification, EUBO PUR hot-melt adhesives will continue to be optimized to meet the growing industry demand for high-performance bonding materials, driving continuous innovation and development in automotive interior displays.

With the continuous development of consumer electronics, TWS Bluetooth earphones have become mainstream in the market due to their lightweight and wireless advantages. In the design and manufacturing of TWS Bluetooth earphones, adhesives play a critical role. EUBO’s PUR hot-melt adhesive provides efficient bonding, sealing, and protection for various components of the earphones, meeting the requirements for miniaturization, precision, and high performance.

TWS Bluetooth Earphone Bonding Solution

EUBO’s UR 6140 hot-melt adhesive solution is specifically designed for TWS Bluetooth earphones, capable of meeting the demands of their complex structures. Particularly for small components such as earphone screens, high precision and consistency of the adhesive are critical. UR 6140 offers excellent initial bonding strength, high-temperature resistance, and chemical stability, ensuring the earphones remain reliable under various conditions. Its environmentally friendly formula, 100% solid content, and solvent-free characteristics comply with international environmental standards while ensuring safety during the manufacturing process.

UR6140 Hot-Melt Adhesive Applications

UR 6140 hot-melt adhesive is widely used in multiple key components of TWS Bluetooth earphones, including the front housing of the earphone cavity, charging contact modules, speaker module FPC fixation, and battery securing. Through precise dispensing processes, UR 6140 provides stable bonding strength while offering excellent water- and dust-resistant properties, significantly enhancing the earphones’ sealing performance and durability.

Features of EUBO UR 6140 Adhesive

High Initial Bonding Strength:

Rapidly forms a strong bond, allowing for short or even no pressure curing.

Cold and Humidity Resistance:

Maintains excellent performance under extreme temperature and humidity, ensuring earphone stability in various climates.

Water and Sweat Resistance:

Ideal for earphones and other consumer electronics, effectively resisting moisture and sweat.

Excellent Adhesion:

Provides strong bonding across multiple substrates, ensuring the stability of earphone components.

Weather and Chemical Resistance:

Retains outstanding adhesion even in harsh conditions such as humidity, sweat, and salt spray.

100% Solid Content, Solvent-Free:

Environmentally friendly and safe, compliant with international environmental standards.

EUBO provides TWS Bluetooth earphone manufacturers with efficient and reliable PUR hot-melt adhesive solutions, helping earphones achieve optimal performance in precision structure, lightweight design, and durability, meeting the market demand for high-quality Bluetooth earphones.

PUR Hot Melt Adhesive (full name: moisture-curable reactive polyurethane hot melt adhesive) is a high-performance adhesive that is solid at room temperature and melts into a liquid upon heating. Its unique reactive curing mechanism allows it to rapidly cure under the influence of ambient moisture, forming a strong chemical structure. PUR hot melt adhesive exhibits excellent adhesion to a wide range of materials, including metals, plastics, glass, and rubber, and is widely used in fields such as lithium batteries, automotive, and home appliances.

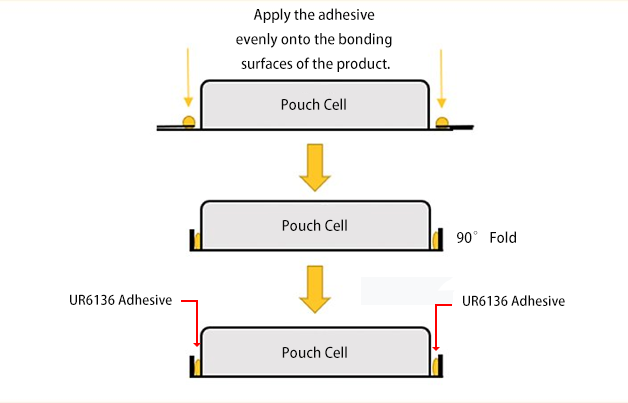

Reasons for Using PUR Edge-Folding Adhesive in Polymer Lithium Batteries

In traditional pouch cell manufacturing, the edges of the cells are sealed with adhesive tape to maintain the cell’s appearance and dimensions, as well as to prevent external short circuits. While this method is effective, the increasing demand for higher energy density in lithium batteries has led to the gradual replacement of tape sealing with adhesive-based edge-folding processes. The adhesive edge-folding process optimizes the battery structure, improving volumetric energy density while reducing production costs. This new process not only enhances production efficiency but also increases automation levels on the production line and improves the yield of quality products.

The application of PUR edge-folding adhesive in this new process addresses the limitations of traditional edge-sealing methods in terms of stability and production efficiency, making it the preferred solution for side bonding in polymer lithium batteries.

Advantages of EUBO PUR Edge-Folding Adhesive

The main advantages of PUR edge-folding adhesive lie in its excellent high-temperature peel resistance and strong adhesion, ensuring secure bonding of battery sides even under high-temperature operating conditions and preventing bond failure. In addition, the adhesive features fast curing, low odor, and a solvent-free, environmentally friendly formulation. These properties not only meet safety and environmental standards but also enhance production line automation, reduce manual operations, and improve production efficiency and product yield.

Features of UR 6136 PUR Edge-Folding Adhesive

Excellent Adhesion: Provides outstanding bonding strength to various aluminum-plastic film substrates, ensuring dimensional stability of the battery.

High-Temperature and Weather Resistance: After curing, the adhesive maintains its strength under high-temperature conditions and exhibits excellent weather resistance, suitable for a variety of environmental conditions.

High Mechanical Performance: The cured PUR adhesive has good toughness, able to withstand vibration and mechanical stress, preventing bond failure due to external forces.

Environmentally Friendly and Solvent-Free: Formulated with 100% solid content and no solvents, compliant with environmental standards, with no harmful gas emissions, ensuring production safety.

Application Scenario:

The UR 6136 PUR adhesive is primarily used for side edge-folding bonding in polymer lithium batteries, ensuring stable cell edge sealing, preventing cell deformation or short circuits, and thereby enhancing battery safety and performance.