1. Why Do Electronic Products Need Potting Adhesives?

Potting adhesives are indispensable materials in the electronics industry, playing a key role in ensuring the safety, reliability, and longevity of electronic products. Their necessity can be highlighted in the following aspects:

Enhanced Protection and Structural Strength:

-

Physical Protection: After curing, potting adhesives form a protective layer that significantly enhances the overall structural strength of electronic components, improving resistance to external impacts, vibrations, and mechanical stresses.

-

Environmental Sealing: They effectively prevent direct exposure of internal components and circuits, providing excellent barriers against water, moisture, dust, and corrosion, thus protecting delicate circuitry from harsh environments.

Improved Electrical Performance and Miniaturization:

-

Reliable Insulation: Potting adhesives greatly enhance insulation between specialized internal components and complex circuits, preventing short circuits and leakage, ensuring safe operation of the device.

-

Facilitates Miniaturization: The filling and protection provided by potting adhesives help secure micro-components, supporting lightweight and compact design in electronic products.

-

Addressing Thermal Challenges:

Modern electronic products feature high precision and high power density, which can easily lead to excessive component temperatures, causing failures and shortening product lifespan.

Potting adhesives—especially thermally conductive types—act as a critical thermal management medium. When applied inside electronic products, they efficiently transfer heat generated by internal components to the casing, significantly improving overall heat dissipation performance.

Ensuring Comprehensive Performance:

High-quality potting adhesives not only provide excellent shock resistance, sealing, and thermal conductivity after curing, but also offer good heat resistance, flame retardancy, weatherability (resistance to thermal cycling, UV, etc.), and long-term stability.

2. Core Functions of EUBO Potting Adhesives

EUBO potting adhesives are designed to meet the needs of electronic products, providing the following key functions:

-

Structural Reinforcement & Impact Resistance:

Forms a tough protective layer after curing, enhancing the overall structural strength of electronic devices and effectively resisting external impacts and vibrations.

-

Electrical Insulation & Miniaturization Support:

Significantly improves insulation between internal components and circuits, ensuring electrical safety. Its filling properties also support miniaturization and lightweight design of devices.

-

Comprehensive Environmental Protection:

Prevents sensitive components and circuits from direct exposure, providing excellent protection against water, moisture, dust, and corrosion.

-

Multifunctional Performance Assurance:

Once fully cured, the adhesive offers thermal conductivity, flame retardancy, high/low temperature resistance, dust protection, and circuit shielding, ensuring the safe and stable operation of electronic components.

3. Key Advantages of EUBO Potting Adhesives

In addition to the core functions, EUBO potting adhesives feature excellent processing and usage characteristics:

-

Excellent Processability: Low viscosity and strong penetration during potting, fully filling fine gaps and encapsulating components.

-

High Stability: Components are stable, easy to store, and have a long shelf life, suitable for large-scale automated production lines.

-

Superior Curing Performance: Minimal filler sedimentation during curing, low risk of phase separation, ensuring uniform and consistent performance.

-

Outstanding Comprehensive Properties: After curing, exhibits excellent flame retardancy, weatherability, thermal conductivity, resistance to high/low temperature cycles, and water resistance.

4. Typical Applications of EUBO Potting Adhesives

EUBO potting adhesives are widely used in electronic components requiring protection, insulation, and thermal management, including but not limited to:

-

Power & Drive: Transformers, high-voltage packs, rectifiers, filters, drivers, igniters, ignition coils, power controllers, aquarium pumps, energy-saving modules.

-

Lighting: LED lighting, LED barrier lights, LED modules.

-

Security & Sensing: Electronic locks, magnetic locks, electronic sensing modules.

-

Automotive Electronics: Xenon lamps, light boosters.

-

Others: Capacitors, negative ion generators, etc.

Application Benefits: Provides reliable potting and filling, circuit shielding, electrical insulation, and moisture/water protection for the above components.

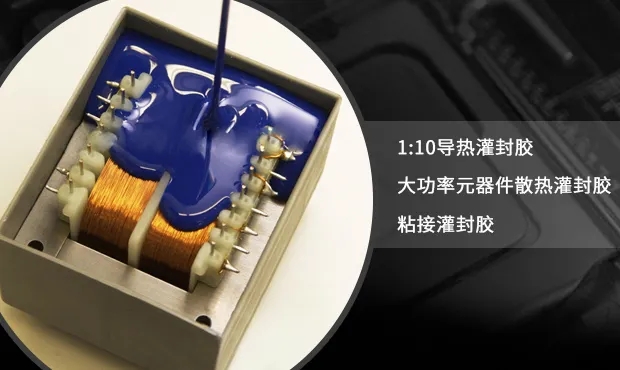

EUBO Electronic Adhesive Solutions

EUBO offers a comprehensive range of electronic adhesive products to meet diverse needs, including:

These products are widely applied to various electronic components, ensuring product safety, long-term reliability, and environmental compliance.

Contact EUBO today to obtain professional and reliable electronic adhesive solutions!