PUR Hot Melt Adhesive (full name: moisture-curable reactive polyurethane hot melt adhesive) is a high-performance adhesive that is solid at room temperature and melts into a liquid upon heating. Its unique reactive curing mechanism allows it to rapidly cure under the influence of ambient moisture, forming a strong chemical structure. PUR hot melt adhesive exhibits excellent adhesion to a wide range of materials, including metals, plastics, glass, and rubber, and is widely used in fields such as lithium batteries, automotive, and home appliances.

Reasons for Using PUR Edge-Folding Adhesive in Polymer Lithium Batteries

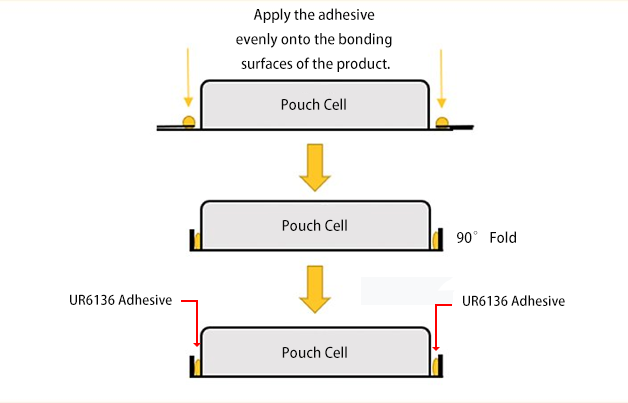

In traditional pouch cell manufacturing, the edges of the cells are sealed with adhesive tape to maintain the cell’s appearance and dimensions, as well as to prevent external short circuits. While this method is effective, the increasing demand for higher energy density in lithium batteries has led to the gradual replacement of tape sealing with adhesive-based edge-folding processes. The adhesive edge-folding process optimizes the battery structure, improving volumetric energy density while reducing production costs. This new process not only enhances production efficiency but also increases automation levels on the production line and improves the yield of quality products.

The application of PUR edge-folding adhesive in this new process addresses the limitations of traditional edge-sealing methods in terms of stability and production efficiency, making it the preferred solution for side bonding in polymer lithium batteries.

Advantages of EUBO PUR Edge-Folding Adhesive

The main advantages of PUR edge-folding adhesive lie in its excellent high-temperature peel resistance and strong adhesion, ensuring secure bonding of battery sides even under high-temperature operating conditions and preventing bond failure. In addition, the adhesive features fast curing, low odor, and a solvent-free, environmentally friendly formulation. These properties not only meet safety and environmental standards but also enhance production line automation, reduce manual operations, and improve production efficiency and product yield.

Features of UR 6136 PUR Edge-Folding Adhesive

-

Excellent Adhesion: Provides outstanding bonding strength to various aluminum-plastic film substrates, ensuring dimensional stability of the battery.

-

High-Temperature and Weather Resistance: After curing, the adhesive maintains its strength under high-temperature conditions and exhibits excellent weather resistance, suitable for a variety of environmental conditions.

-

High Mechanical Performance: The cured PUR adhesive has good toughness, able to withstand vibration and mechanical stress, preventing bond failure due to external forces.

-

Environmentally Friendly and Solvent-Free: Formulated with 100% solid content and no solvents, compliant with environmental standards, with no harmful gas emissions, ensuring production safety.

Application Scenario:

The UR 6136 PUR adhesive is primarily used for side edge-folding bonding in polymer lithium batteries, ensuring stable cell edge sealing, preventing cell deformation or short circuits, and thereby enhancing battery safety and performance.