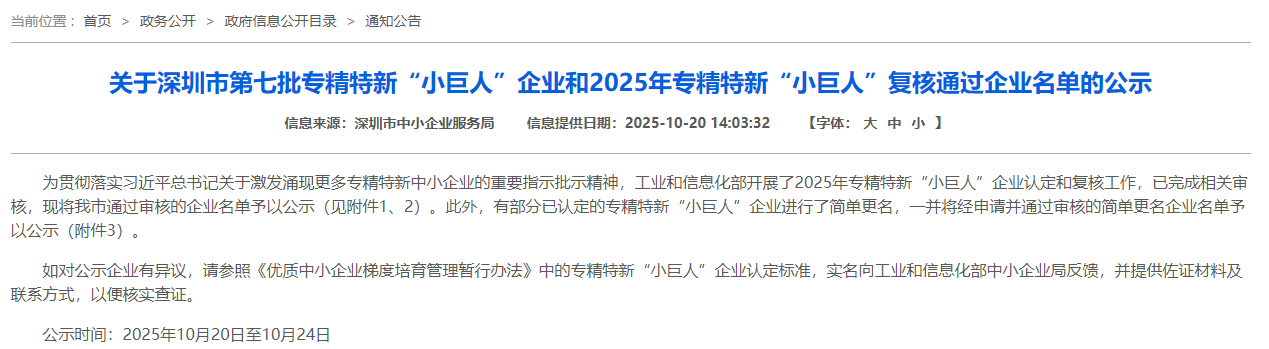

Recently, the Shenzhen Small and Medium-sized Enterprise Service Bureau announced the list of the seventh batch of national-level “Little Giant” specialized and innovative enterprises, as well as the list of enterprises that passed the 2025 review.

After a rigorous review and public announcement, Shenzhen EUBO New Material Technology Co., Ltd. was successfully selected and recognized as a National-Level “Little Giant” Specialized and Innovative Enterprise.

This honor not only fully recognizes EUBO New Material’s comprehensive strength, but also highlights the company’s 25 years of innovation and achievements in the field of new materials.

National-Level “Little Giant” Specialized and Innovative Enterprises

The “Little Giant” specialized and innovative enterprises are a key group of high-quality SMEs cultivated by the Ministry of Industry and Information Technology of China. They represent the leading level of Chinese SMEs in areas such as professional expertise, lean management, technological innovation, and industrial chain collaboration. These enterprises are the core driving force for modernizing the industrial chain and leading high-quality development in the manufacturing sector.

Panoramic Strength | EUBO New Material’s Path to Specialized and Innovative Excellence

🔹Specialization: 25 Years of Deep Engagement in New Materials

Since its establishment in 2000, EUBO New Material has been fully focused on specialty lubricants, electronic adhesives, and functional new materials, forming a complete system from R&D and production to application.

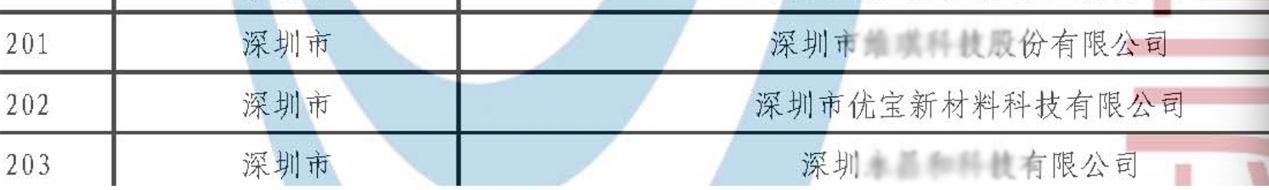

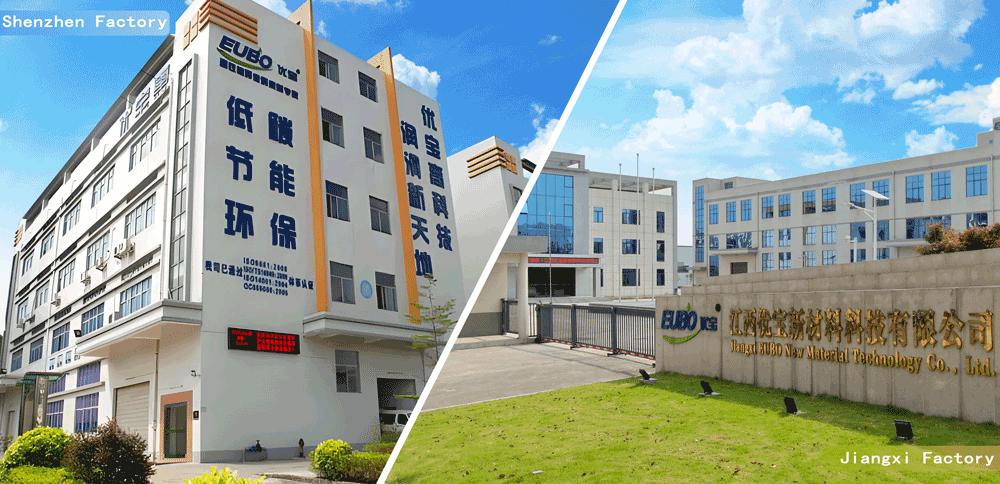

The company has its headquarters and main factory in Shenzhen, as well as the Guangming Martin R&D Center, and a 30,000 m² smart manufacturing base in Yichun, Jiangxi. Guided by market demand and driven by technological innovation, EUBO continuously builds a specialized, systematic, and sustainable new materials industry layout.

🔹Refinement: Rigorous Systems, Quality First

EUBO New Material regards quality as the lifeline of the company and has established a comprehensive, refined management system covering the entire process. The company has obtained multiple international certifications, including ISO9001, IATF16949, ISO14001, and QC080000.

EUBO New Material implements standardized and refined control in raw material selection, process management, and product validation, building its quality reputation through a rigorous system.

🔹Distinctiveness: Innovative Craftsmanship, Setting Industry Benchmarks

EUBO New Material focuses on niche markets, offering a range of products including specialty lubricants, electronic adhesives, and high-performance coatings, widely applied in automotive electronics, smart manufacturing, consumer electronics, and other industries.

Relying on proprietary core technologies and unique processes, EUBO New Material provides customized solutions, serving over 2,000 clients worldwide, including more than 50 Fortune Global 500 companies, and has established itself as an industry benchmark through technology and quality.

🔹Innovation: Technology-Driven with Remarkable Achievements

As a national-level high-tech enterprise, EUBO New Material has established an integrated innovation system encompassing R&D, technology commercialization, and application.

The company has established the Guangdong Engineering Technology Research Center and a Postdoctoral Innovation Base, and collaborates with institutions such as the Institute of Chemistry of the Chinese Academy of Sciences, Central South University, and the Shenzhen Tsinghua University Research Institute to develop degradable and environmentally friendly new materials.

Continuous innovation has enabled EUBO New Material to hold numerous independent intellectual property rights, earning recognition as a national-level high-tech enterprise, one of China’s Top 100 Innovative SMEs, and one of Shenzhen’s Top 100 Self-Innovative Enterprises. Its technological achievements are widely applied across multiple industries.

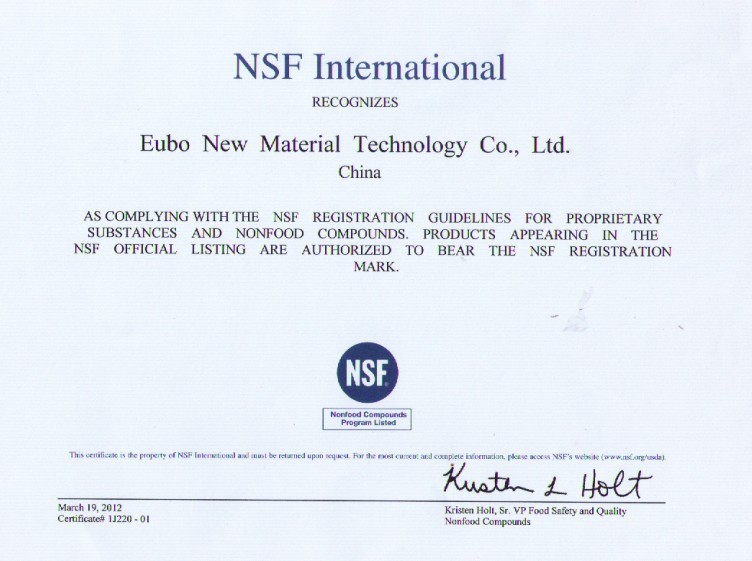

Recently, one of the most authoritative certification bodies in the food processing industry—the NSF (National Sanitation Foundation, USA)—awarded EUBO a plaque recognizing“20 Consecutive Years of NSF International Certification”. EUBO is also among the first domestic companies to achieve NSF certification for 20 consecutive years. This honor not only acknowledges EUBO’s consistent strength in the design, production, and quality management of food-grade lubricants over the past two decades but also serves as a strong support for its continued development in the future.

20 Consecutive Years of NSF International Certification

EUBO’s ability to maintain NSF certification for 20 consecutive years is the result of its continuous investment in product quality and rigorous control standards. NSF food-grade certification indicates that EUBO lubricants comply with the FDA’s food-grade requirements, making them suitable for use in equipment that comes into contact with food, thereby ensuring food safety and hygiene.

EUBO’s lubricants not only comply with FDA regulations but have also obtained international certifications includingROHS, REACH, 23P, Halogen-Free, and EN71-3. All products come withSafety Data Sheets (MSDS)and relevant test reports, ensuring that they are green, environmentally friendly, energy-saving, and low-carbon. Behind these certifications lies EUBO’s rigorous control and continuous improvement across every stage ofproduct R&D, production, and testing.

The Significance of NSF Certification

NSF is a globally leading public health and safety organization, dedicated to developing and promoting standards for product hygiene, safety, and quality. Worldwide, NSF certification is recognized as a mark of high quality, environmental friendliness, and safety. It holds particular importance in thefood, beverage, pharmaceutical, and industrial lubricant sectors. NSF certification covers multiple aspects includingproduction processes, management systems, product formulations, and testing, imposing strict requirements on manufacturing procedures, product quality, safety, and environmental impact.

High Requirements and Challenges of NSF Certification

Obtaining NSF certification is no easy task. It requires companies to conduct strict self-audits and improvements across multiple dimensions to meet high international standards. Specifically, NSF certification involves, but is not limited to, the following aspects:

01. Safety of Raw Materials and Formulations

All raw materials used in production must comply with safety standards and undergo rigorous testing and verification.

02. Strict Control of the Production Process

The production process must meet NSF hygiene and safety requirements, including equipment cleanliness and controlled production environments.

03. Verification of Product Performance

Products must pass multiple performance tests to ensure they meet the intended functional requirements.

04. Continuous Quality Monitoring and Improvement

Companies are required to submit product samples regularly to NSF and have them verified by third-party testing agencies to ensure products consistently meet quality standards.

Due to these stringent requirements, obtaining and maintaining NSF certification is a significant challenge. Companies must achieve high standards in both technology and management while maintaining continuous investment and improvement to ensure their products always comply with strict NSF certification criteria.

Looking Ahead

Receiving NSF international certification for 20 consecutive years is both an honor and a responsibility for EUBO. The company will continue to uphold principles of integrity, innovation, and compliance, strictly following NSF certification requirements and relevant regulations, while dedicating itself to the research, development, and production of food-grade lubricants. Adhering to the principle of “Quality First, Customer Foremost,” EUBO will continuously enhance product quality and safety, striving to provide customers with superior, reliable products and services.

Currently, EUBO’s food-grade lubricants are widely used in various food production equipment, food processing, medical devices, and drinking water applications. The company will continue to invest in technological research and innovation to improve product performance and market competitiveness. Looking to the future, EUBO will maintain a quality- and efficiency-driven development path, steadily enhancing its core competitiveness and brand influence, providing domestic and international customers with high-quality products and services, and jointly promoting the healthy and sustainable development of the industry.

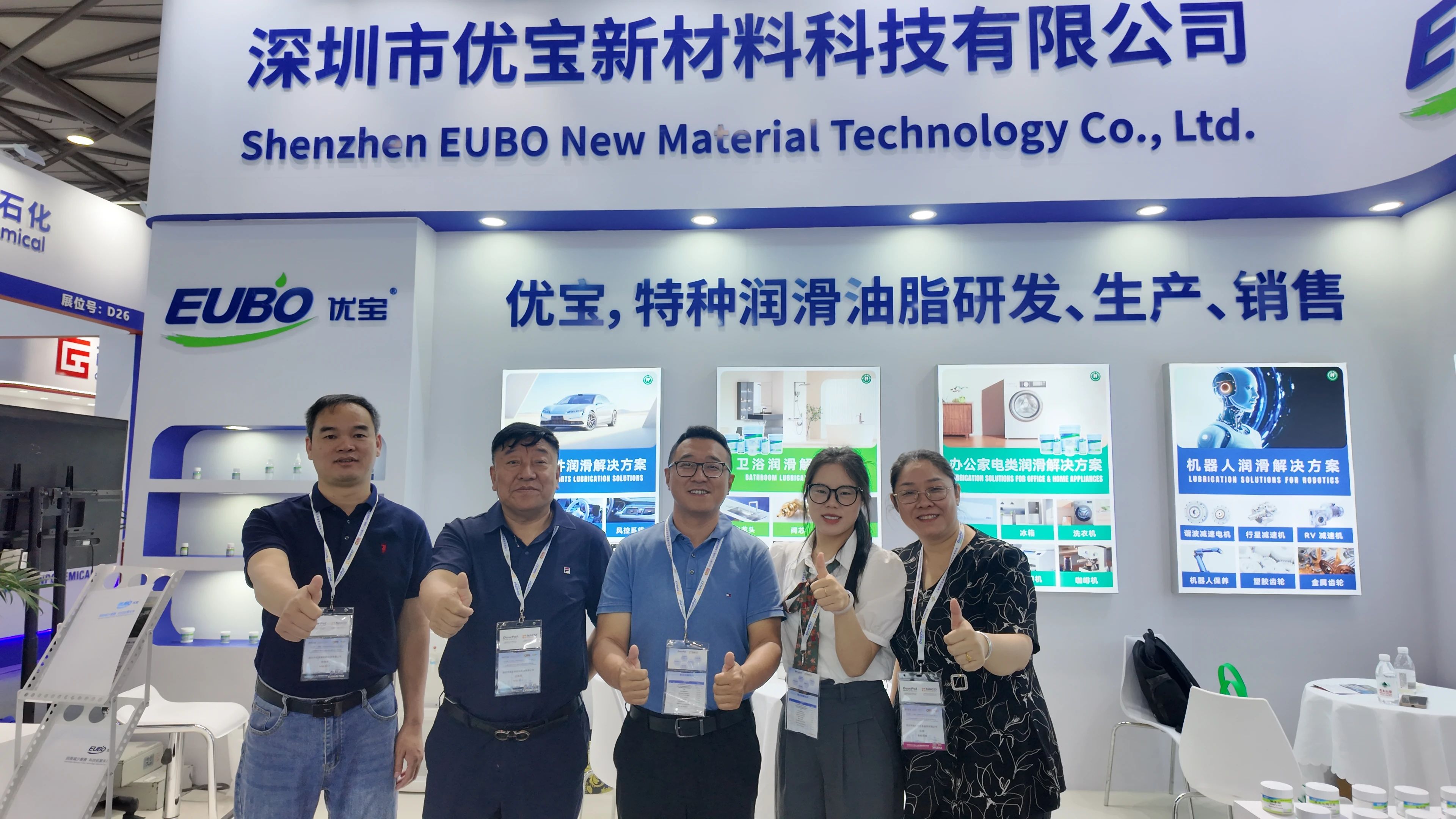

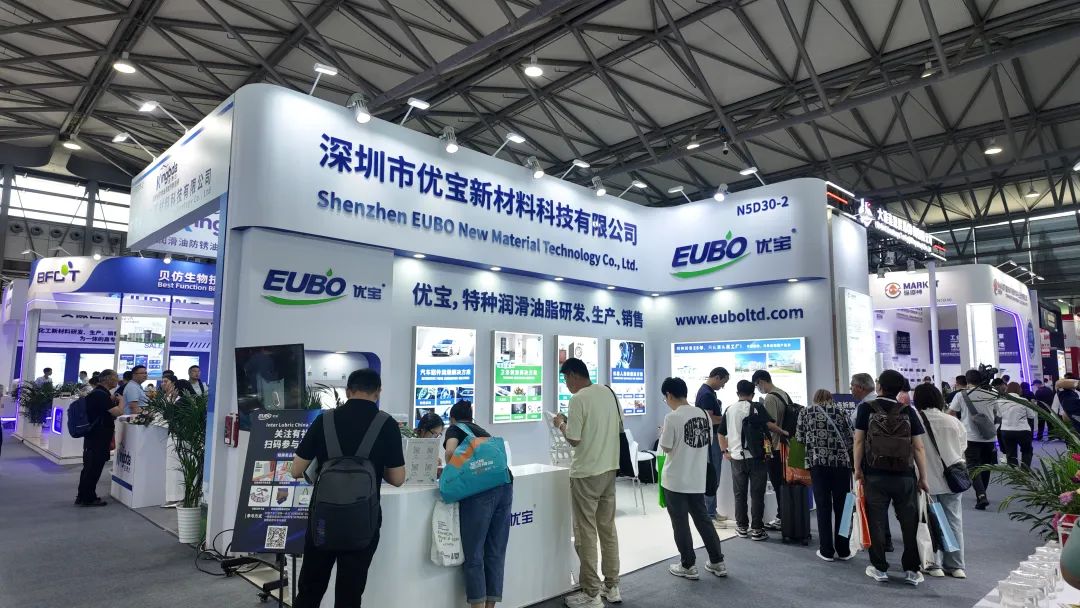

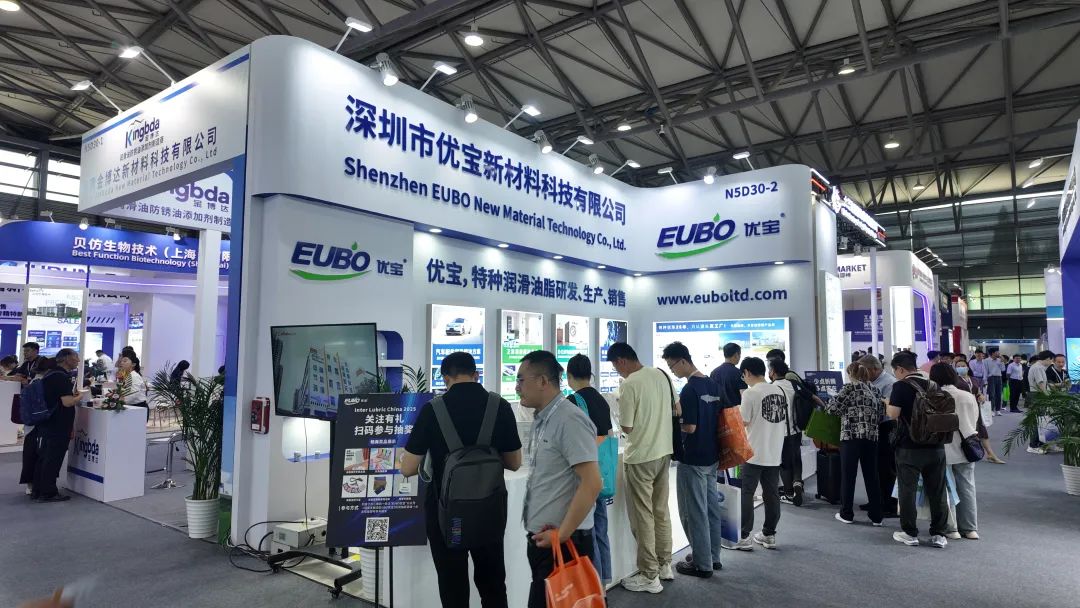

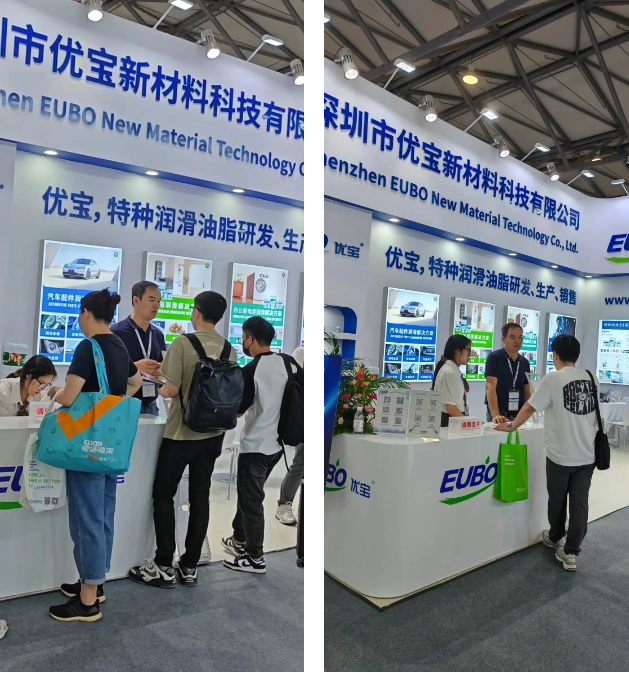

From June 4 to 6, 2025, the 24th Shanghai International Lubricants and Application Technology Expo, together with the Shanghai International Metalworking Fluids and Surface Cleaning Technology Expo, was grandly held in Shanghai. As a leading company in China’s new materials sector, Shenzhen EUBO New Material Technology Co., Ltd. showcased numerous innovative products and technologies, attracting widespread attention from professionals both within and outside the industry.

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000 and headquartered in Guangming District, Shenzhen, is a high-tech enterprise specializing in the research, development, and production of new materials, including lubricants, adhesives, and protective coatings. Leveraging its outstanding technological strength and innovative capabilities, the company has been recognized as one of the first “Specialized, Refined, Distinctive, and Innovative” (专精特新) enterprises in Shenzhen. EUBO has established a 30,000㎡ production base in Yichun, Jiangxi, and operates branch offices in Shanghai, Fujian, Chongqing, Hong Kong, and other locations, with a broad business reach.

At this expo, EUBO New Material showcased its cutting-edge technologies and innovative products in the fields of lubricants, protective materials, and adhesives. The company’s specially developed greases are designed for extreme conditions, including high speed, heavy load, high or low temperatures, low noise, water resistance, sealing, corrosion protection, and lubrication, demonstrating EUBO’s deep technical expertise in specialty grease development. In addition, EUBO’s adhesive product portfolio covers module edge-bonding adhesives, UV-curable adhesives, structural adhesives, bottom-filling adhesives, PUR hot-melt adhesives, coating adhesives, and nano water-repellent agents. These products are widely applied across electronics, automotive, and machinery industries, providing customized solutions for clients in diverse sectors.

EUBO New Material has obtained certifications for ISO9001, IATF16949, and QC080000 quality management systems, ISO14001 environmental management system, and ISO45001 occupational health and safety management system. These certifications signify that the company has achieved internationally advanced standards in quality management, environmental protection, and occupational health and safety. Leveraging its excellent product quality and comprehensive management systems, EUBO New Material has gained strong market recognition and received numerous honors, including being a standing director unit of the Shenzhen New Materials Industry Association, one of China’s Top 100 Innovative SMEs, and one of Shenzhen’s Top 100 Independently Innovative SMEs.

With high-quality products and services, the company has earned the trust of over 1,000 global clients, including more than 30 Fortune 500 companies. At this expo, EUBO’s booth attracted significant attention from domestic and international visitors, who expressed strong interest in the company’s products and technologies and engaged in in-depth discussions with company representatives to explore potential cooperation opportunities.

EUBO New Material’s R&D Engineering Center has been recognized by the Provincial Department of Science and Technology as the “Guangdong Provincial Engineering Technology Research Center for Advanced Lubrication and Protective Materials” and also serves as a Postdoctoral Innovation and Practice Base in Shenzhen. The company has established long-term and stable technical collaborations with multiple research institutions, including the Shenzhen Tsinghua University Research Institute, Southern University of Science and Technology, and the Institute of Chemistry, Chinese Academy of Sciences. Its R&D team consists of over 30 professionals, including local leading talents of Shenzhen, reserve talents, postdoctoral researchers, senior engineers, and experienced R&D engineers, demonstrating strong capabilities in scientific research, product development, and technological innovation.

The center houses multiple specialized laboratories, including an Advanced Materials Laboratory, Pilot Production Base, Precision Instrument Room, Reliability Laboratory, Physical and Chemical Laboratory, and Test Bench Laboratory, equipped with over 100 professional new material testing and analysis instruments, capable of handling more than 200 testing projects. At this expo, EUBO New Material showcased its advanced R&D equipment and testing capabilities, highlighting the company’s strong strengths in technological innovation and product quality control.

Shenzhen EUBO New Material Technology Co., Ltd.’s impressive presence at the 2025 Shanghai International Lubricants and Application Technology Expo and the Shanghai International Metalworking Fluids and Surface Cleaning Technology Expo fully demonstrated its robust capabilities and innovative spirit as an industry leader. Looking ahead, EUBO New Material will continue to increase R&D investment, deepen collaborations with research institutions, and continuously enhance product performance and service quality, providing global clients with superior new material solutions and driving industry development and progress.

Qin Jingteng, Member of the Standing Committee of Guangming District, Visits EUBO for Inspection and Research

Recently, Qin Jingteng, Member of the Standing Committee of Guangming District, along with personnel from the District Committee’s United Front Work Department, the Federation of Industry and Commerce, Matian Subdistrict Office, and the Matian Community Enterprise Service Center, visited EUBO New Material to conduct an inspection and understand the company’s development, while listening to enterprise needs. Chairman Yue Fengshu provided Qin and his delegation with a report on EUBO’s development.

Qin and his team held a meeting with the company’s senior management. At the meeting, R&D Director Li Shicheng introduced the company’s product development efforts, and Dr. Yang Bin, Assistant to the General Manager, reported on recent industry-university-research cooperation projects with the Institute of Chemistry, Chinese Academy of Sciences, and Southern University of Science and Technology, as well as the progress of scientific research projects. Qin expressed strong approval and support for these initiatives.

Qin also inquired about any challenges the company faces in production and operations that may require government support, and sought opinions on the enterprise services provided by the Matian Subdistrict Office. He emphasized that, as a key enterprise in Guangming District, EUBO will receive strong support from local party committees, government departments, and relevant authorities. Any difficulties encountered during development will be actively coordinated and resolved. Finally, Qin encouraged EUBO to continue innovating boldly under new business models and formats, strengthen product R&D, and further expand and enhance the company’s capabilities.

Qin highly recognized EUBO’s pragmatic and earnest approach, noting that the company’s products not only yield significant economic benefits but also deliver substantial social value. He expressed hope that EUBO will continue to grow and thrive, rooted in Guangming.

From August 8 to 10, 2025, the World Battery & Energy Storage Industry Expo will be grandly held at Area A of the Guangzhou Canton Fair Complex. As a major event for the Asia-Pacific new energy industry, the exhibition will bring together over 2,000 renowned domestic and international companies, showcasing cutting-edge technologies such as lithium batteries, sodium-ion batteries, solid-state batteries, and hydrogen fuel cells, as well as application scenarios in energy storage, electric vehicles, and 3C consumer electronics, driving high-quality development in the new energy sector.

Exhibition Date: August 8–10, 2025

Exhibition Venue: Area A, Guangzhou Canton Fair Complex

EUBO Booth: Hall 4.1, C308

EUBO Focuses on Battery Adhesive & Encapsulation Solutions

In response to the growing demand for encapsulation and bonding in segments such as power batteries, energy storage batteries, and 3C digital batteries, EUBO New Material will showcase a range of electronic encapsulation adhesives at this exhibition, providing reliable bonding and sealing solutions for the battery industry.

Featured Products:

▶ Structural & Adhesive Solutions:

Including PUR hot melt adhesives, epoxy adhesives, acrylic adhesives, and silicone adhesives. Some products employ UV curing technology to achieve fast and precise positioning and efficient assembly, widely used in various structural fixation and module bonding scenarios.

▶ Encapsulation & Protective Materials:

Including conformal coating adhesives, potting adhesives, sealing adhesives, and nano water-repellent agents, providing moisture, dust, corrosion, and mechanical protection for electronic components.

▶ Functional Adhesives:

Including thermal conductive adhesives and electrically conductive adhesives, enhancing heat dissipation, electrical performance, and overall reliability.

These products are widely used in cell encapsulation, battery module assembly, and terminal sealing, compatible with lithium-ion, sodium-ion, and solid-state battery systems. They offer high bonding strength and excellent weather resistance, helping companies build high-performance, safe, and reliable energy storage systems and end products.

On-site Interaction & Engagement

Technical Sharing: Insights into trends in power battery and energy storage encapsulation applications.

Face-to-Face with Experts: Personalized product selection and application consultation.

Case Demonstrations: Showcasing successful applications by key customers in electric vehicles, energy storage systems, and other fields.

About EUBO

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000, is a national high-tech enterprise and one of the first “Specialized, Refined, Distinctive, and Innovative” (SRDI) companies, focusing on the research, development, and manufacturing of adhesives and lubricants. The company is headquartered in Shenzhen, operates a 30,000㎡ modern production base in Yichun, Jiangxi, and has branch offices across China.

EUBO has obtained multiple quality and management system certifications including ISO9001, IATF16949, and ISO14001. Its products are widely used in electronics, automotive, and new energy industries, serving over 1,000 global customers, including more than 30 Fortune Global 500 companies.

You are sincerely invited to visit Booth C308 and explore the future of electronic encapsulation materials with EUBO, discussing new opportunities in the era of green energy!

AGIC + IOTE 2025, the 24th International Internet of Things Exhibition · Shenzhen, will grandly open from August 27–29, 2025, at the Shenzhen World Exhibition & Convention Center (Bao’an New Venue).

The exhibition will span 80,000 square meters, bringing together over 1,000 leading enterprises in the industry. With a focus on cutting-edge “AI + IoT” applications, it will cover multiple fields including smart cities, Industry 4.0, smart homes, smart logistics, smart hardware, and digital ecosystems, presenting a high-level intelligent event for the industry.

Shenzhen World Exhibition & Convention Center (Bao’an New Venue)

Hall 11, Booth 11B21

August 27–29, 2025

EUBO New Material Company Profile

Shenzhen EUBO New Material Technology Co., Ltd., founded in 2000 and headquartered in Shenzhen, operates a 30,000㎡ manufacturing base in Yichun, Jiangxi, and has branch offices in Shanghai, Fujian, Chongqing, and Hong Kong. As one of the first “Specialized, Refined, Distinctive, and Innovative” high-tech enterprises, the company has obtained certifications including ISO9001, IATF16949, ISO14001, and ISO45001. Its product portfolio covers electronic adhesives, lubricants, and functional protective materials, serving over 1,000 global customers, including more than 30 Fortune Global 500 companies.

EUBO Exhibit Highlights – Structural & Adhesive Solutions:

PUR hot melt adhesives, OLED module frame adhesives, epoxy adhesives, acrylic adhesives, and silicone adhesives. Some products are equipped with UV curing technology, enabling fast and precise positioning as well as efficient assembly.

Encapsulation & Protective Materials:

Conformal coating adhesives, potting adhesives, sealing adhesives, and nano water-repellent agents, providing comprehensive protection for electronic components.

Functional Adhesives:

Thermal conductive adhesives and electrically conductive adhesives, enhancing heat dissipation and electrical performance, supporting stable and efficient operation of smart devices.

You are cordially invited to visit EUBO New Material at Hall 11, Booth 11B21, Shenzhen World Exhibition & Convention Center (Bao’an New Venue) from August 27–29, 2025. We look forward to exploring industry trends and collaboration opportunities with you!